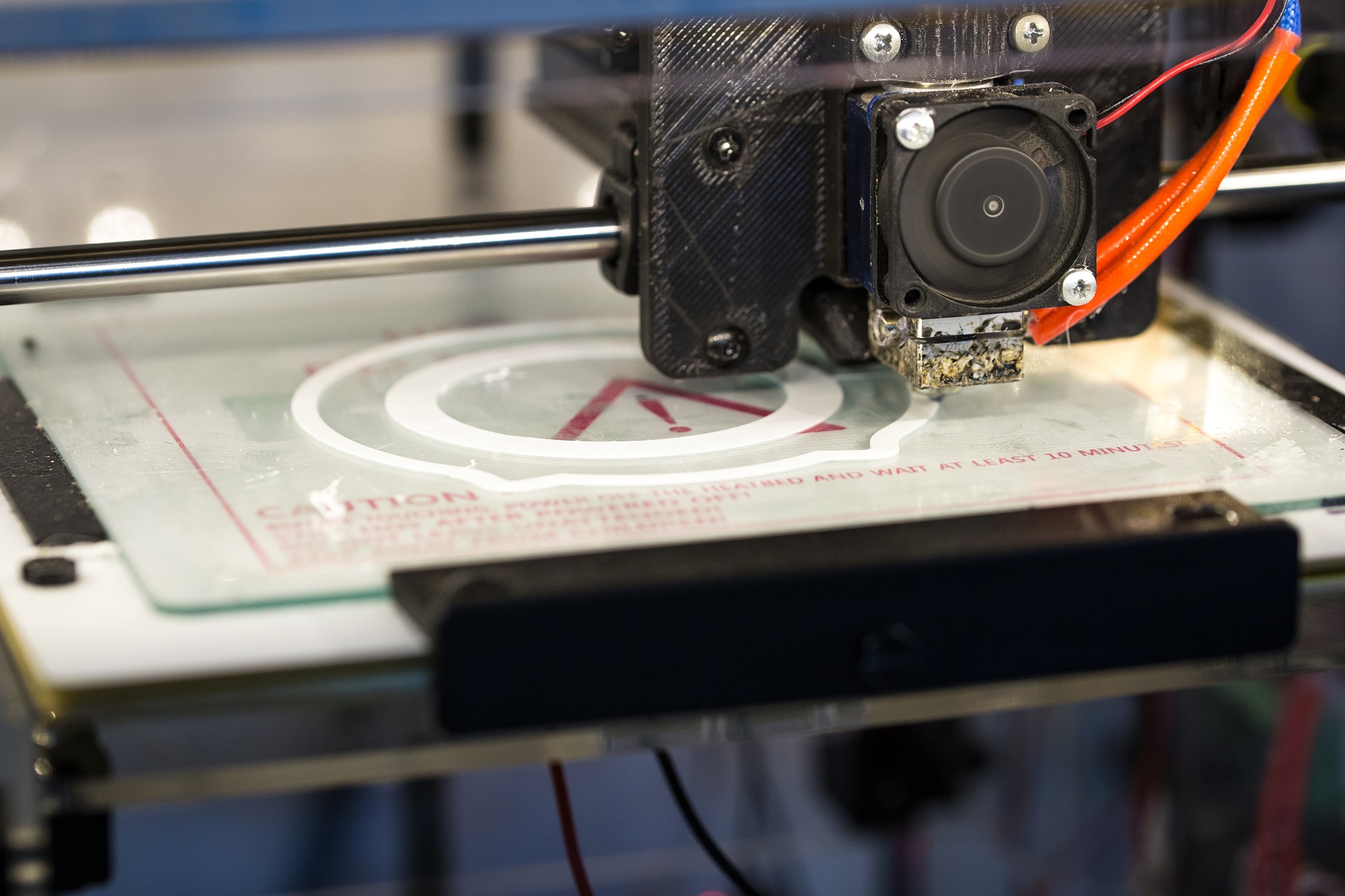

3D Printing

As technology continues to advance, 3D printing has become a fast, flexible solution to many industrial challenges. From rapid prototyping to on-demand replacement parts, it’s transforming how manufacturing and maintenance teams stay on schedule.

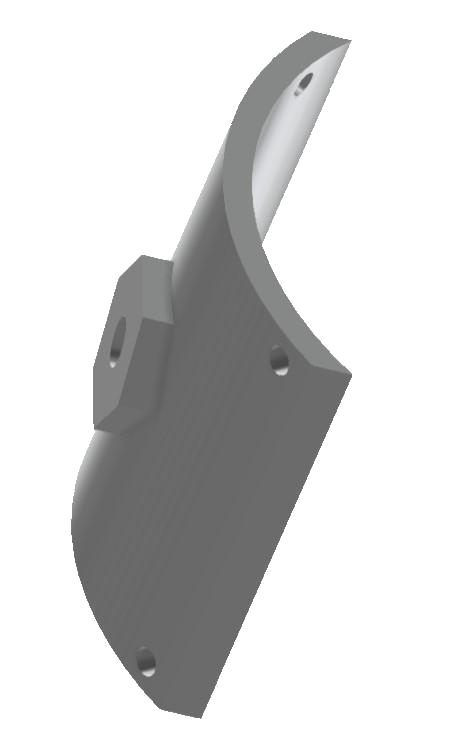

Britton Electronics & Automation offers both FDM (Fused Deposition Modeling) and resin printing capabilities in-house. Our resin printer features a large print area and delivers exceptionally high detail—ideal for precision components, functional prototypes, and parts that require a smooth finish or tight tolerances.

Resin printing—also known as SLA or MSLA—uses liquid photopolymer cured by UV light to produce parts with fine resolution, crisp edges, and minimal post-processing. It’s especially effective for:

- Enclosures or covers that require a professional finish

- Connectors, clips, and brackets with tight dimensional needs

- Replacement parts that must fit into existing assemblies

- Prototypes where form and function must be tested at production quality

We use industrial-grade resins selected for mechanical strength, thermal resistance, and chemical durability—making these parts suitable for demanding environments.

We also offer FDM printing for fast-turnaround jobs and durable material testing. FDM is ideal for prototyping mechanical parts, brackets, jigs, and production aids using filament types like PLA, PETG, ABS, Carbon Fiber-infused filament, Nylon, and Polycarbonate. Both technologies allow us to produce custom parts in hours—not days—keeping your project or plant on schedule without relying on long lead times or costly outsourced machining.

What used to take days or weeks can now be done in hours. Keeping production moving while avoiding delays from part shortages or custom fabrications has never been easier.

|