| 2026-01-14 11:19:18 |

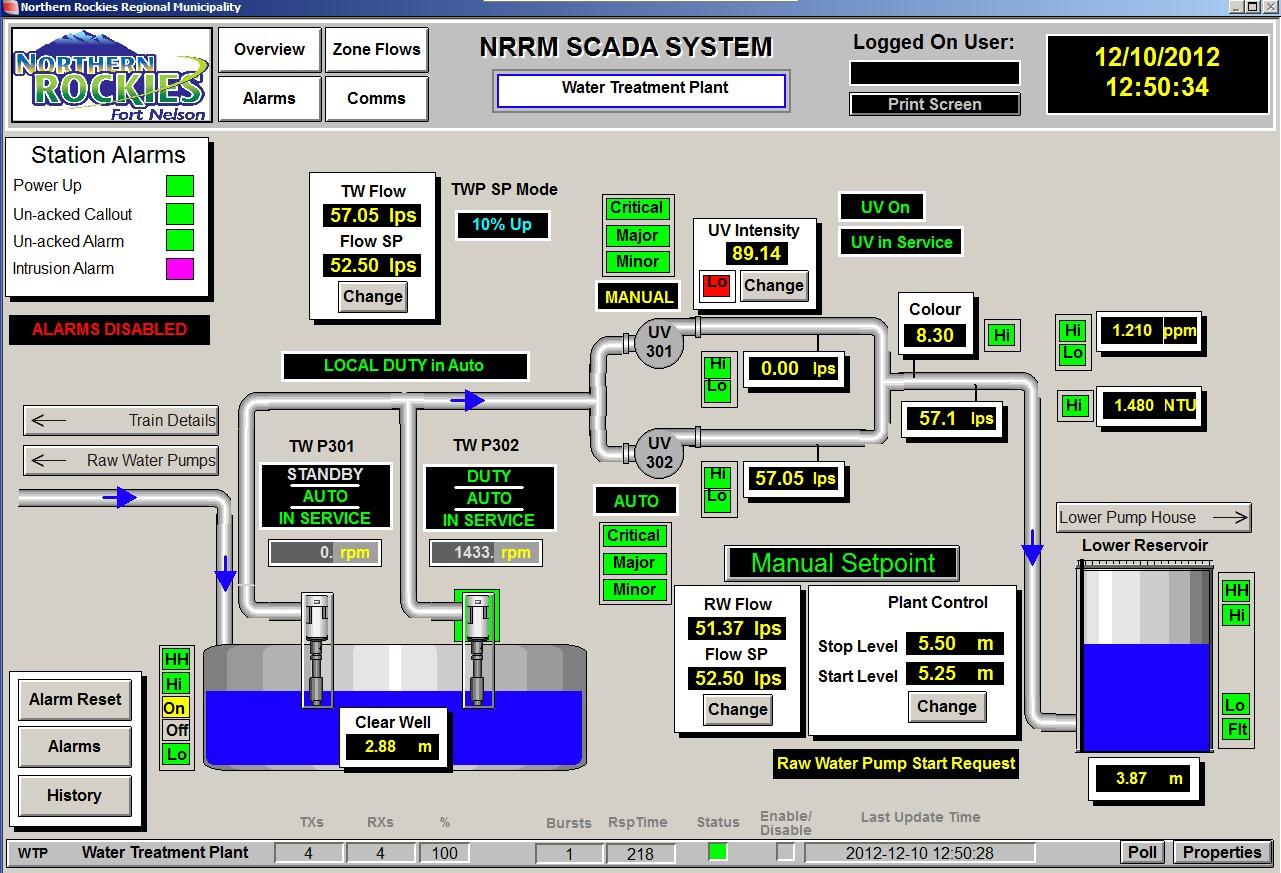

How SCADA Systems Pay for Themselves in Water and Wastewater Plants

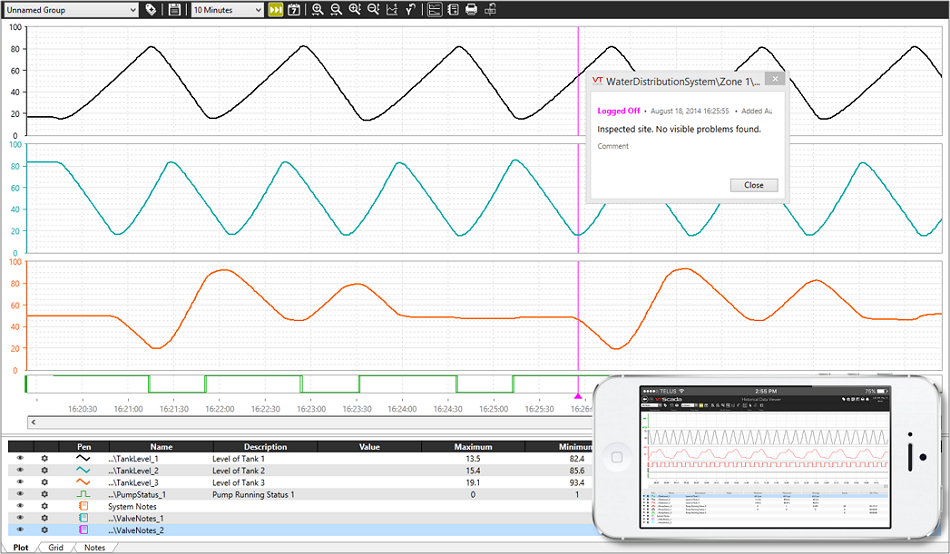

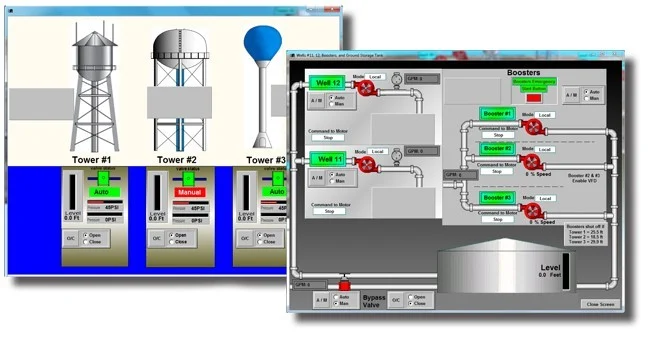

SCADA systems are often viewed as a cost. In reality, they are one of the few investments in water and wastewater operations that consistently return more than they cost.

Not through flashy dashboards or complex analytics, but through simple, measurable operational savings.

Labor Is the First Payback

Without SCADA, operators rely on physical site checks, manual logs, phone calls, and guesswork.

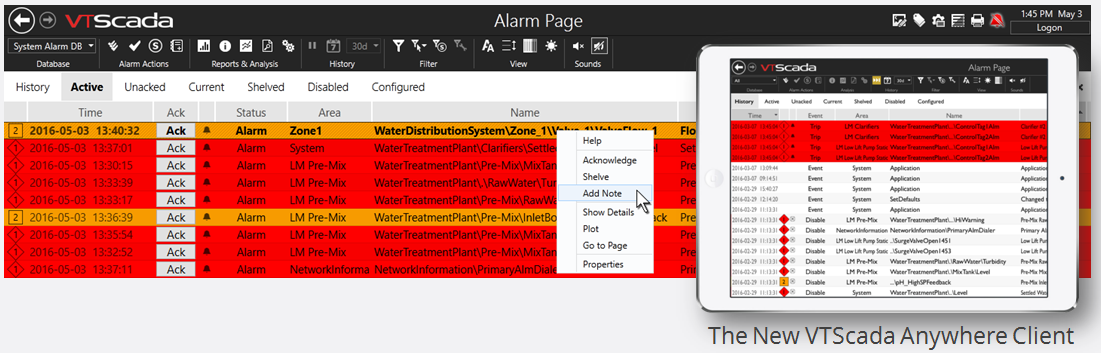

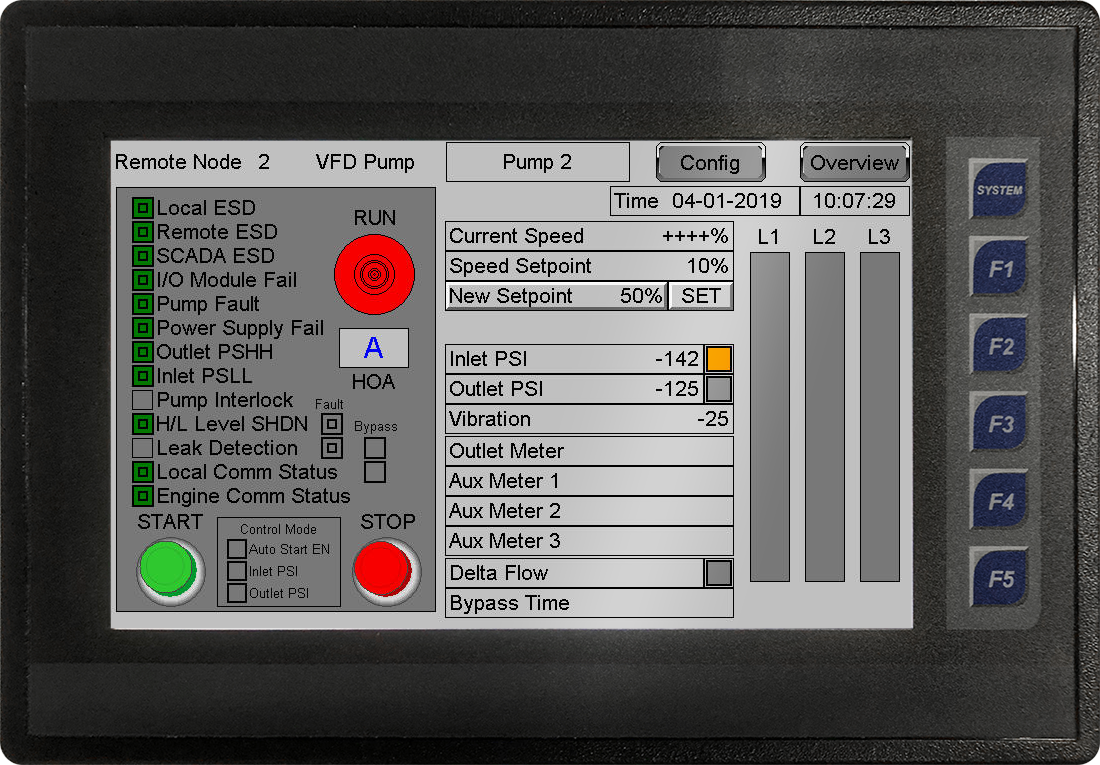

SCADA reduces the number of routine trips required just to check on things. Operators can quickly see which pump is running, which one failed, and whether a site actually needs attention.

Fewer unnecessary trips means less overtime, less fuel usage, less wear on vehicles, and more time spent on work that actually matters.

Early Detection Prevents Expensive Failures

Equipment rarely fails without warning. Current draw changes. Run times increase. Starts become inconsistent.

SCADA exposes those changes before they become emergencies.

Catching a problem early can mean replacing a component instead of a pump, fixing a sensor instead of flooding a station, and scheduling a repair instead of responding at night. Avoiding even one major failure can justify the system.

Energy Savings Add Up Quietly

.jpg)

SCADA allows plants to balance pump usage, rotate equipment evenly, avoid running pumps harder than necessary, and identify inefficient operation.

Even modest efficiency improvements compound over time. Energy savings do not announce themselves, but they show up every month on the utility bill.

Documentation and Compliance Become Easier

Manual recordkeeping is time-consuming and error-prone.

SCADA systems can automatically log run times, levels, alarms, and operator actions.

This data supports regulatory reporting, simplifies audits, and protects operators and municipalities. Time saved on paperwork is time returned to operations.

Reduced Dependence on Tribal Knowledge

Many plants rely on a few individuals who just know how it works.

SCADA makes system behavior visible, provides clear alarms and status, and reduces reliance on memory and guesswork.

That matters when staff retire, turnover occurs, or outside help is required. Systems that can explain themselves cost less to maintain.

The Real Payback Is Predictability

The biggest return is not just financial. It is knowing what is happening, where the problem is, and whether immediate action is required.

Predictability reduces stress, mistakes, and emergency decision-making. SCADA does not replace operators. It supports them.

When SCADA Is Done Right

A properly designed SCADA system is scaled to the facility, built with supported hardware, understandable by local staff, and designed for long-term operation.

It does not need to be complex to be effective. When implemented correctly, SCADA does not just pay for itself. It becomes one of the most valuable tools in the plant.

|

|

| 2025-12-26 17:47:53 |

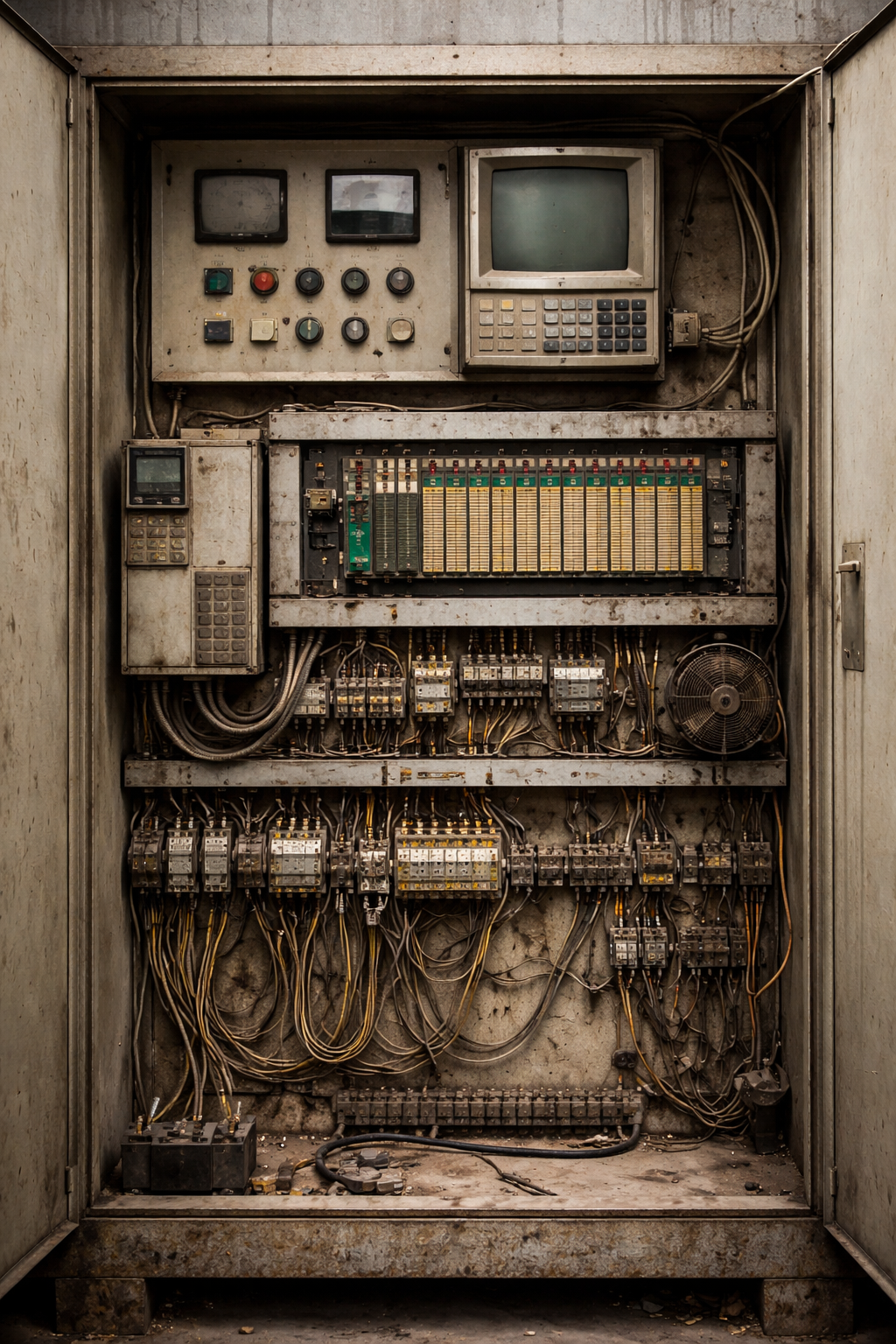

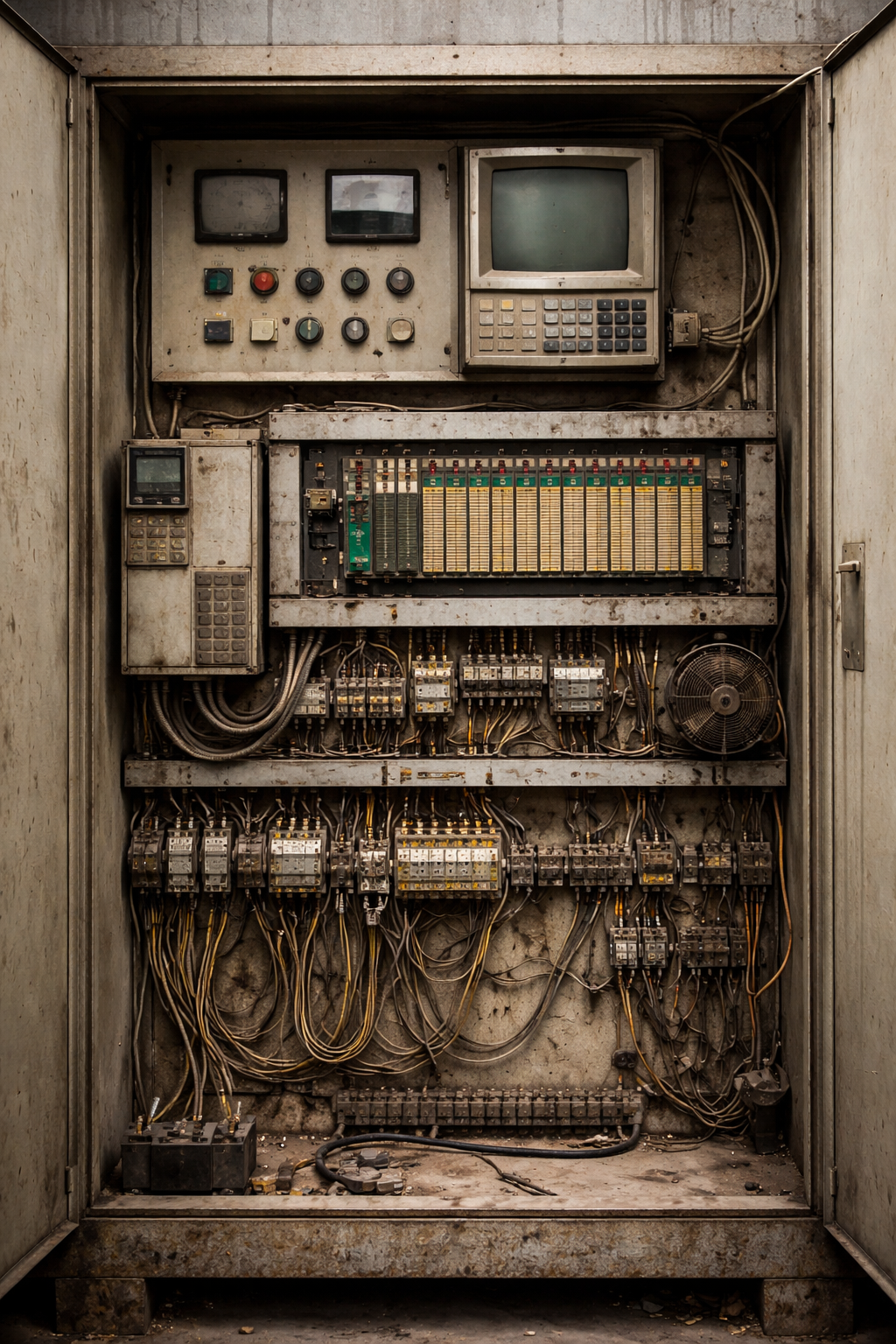

It Worked for 20 Years Until It Didn’t

We hear it all the time: “That system’s been running for 20 years.” And that is true right up until the day it is not.

Control systems rarely fail with a clean warning. They fail when a pump is needed the most, when a storm event hits, when staffing is light, or when replacement parts are weeks or months out.

At Britton Electronics and Automation, we are usually called after the failure when the conversation has already turned into damage control.

Control Systems Do Not Age Gracefully

Mechanical equipment usually gives signs before it fails. Control systems often do not.

Failures show up as drives faulting under load with no prior history, PLCs locking up after a routine power cycle, communications dropping intermittently and then disappearing entirely, or time drift creating alarms that do not align with what operators see in the field.

On paper, the system still works. In reality, it is operating with no margin left.

Obsolete Does Not Mean Broken Until It Does

One of the biggest risks in older systems is not failure itself. It is recovery.

When a drive, PLC, or HMI fails and the model is discontinued, firmware is unavailable, or the spare on the shelf does not match what is installed, troubleshooting quickly turns into redesign under pressure. Temporary fixes become permanent. Costs rise. Downtime stretches longer than expected.

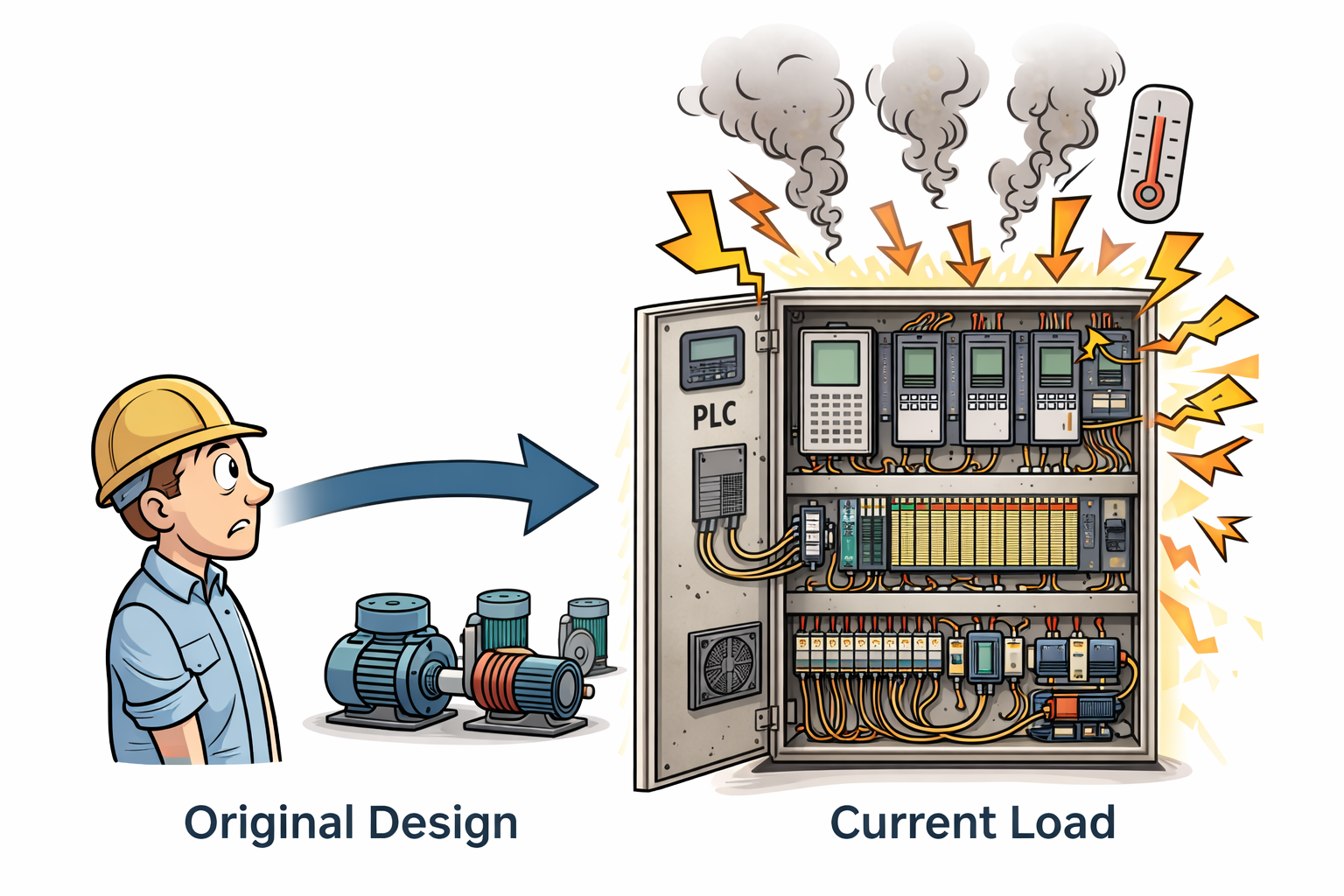

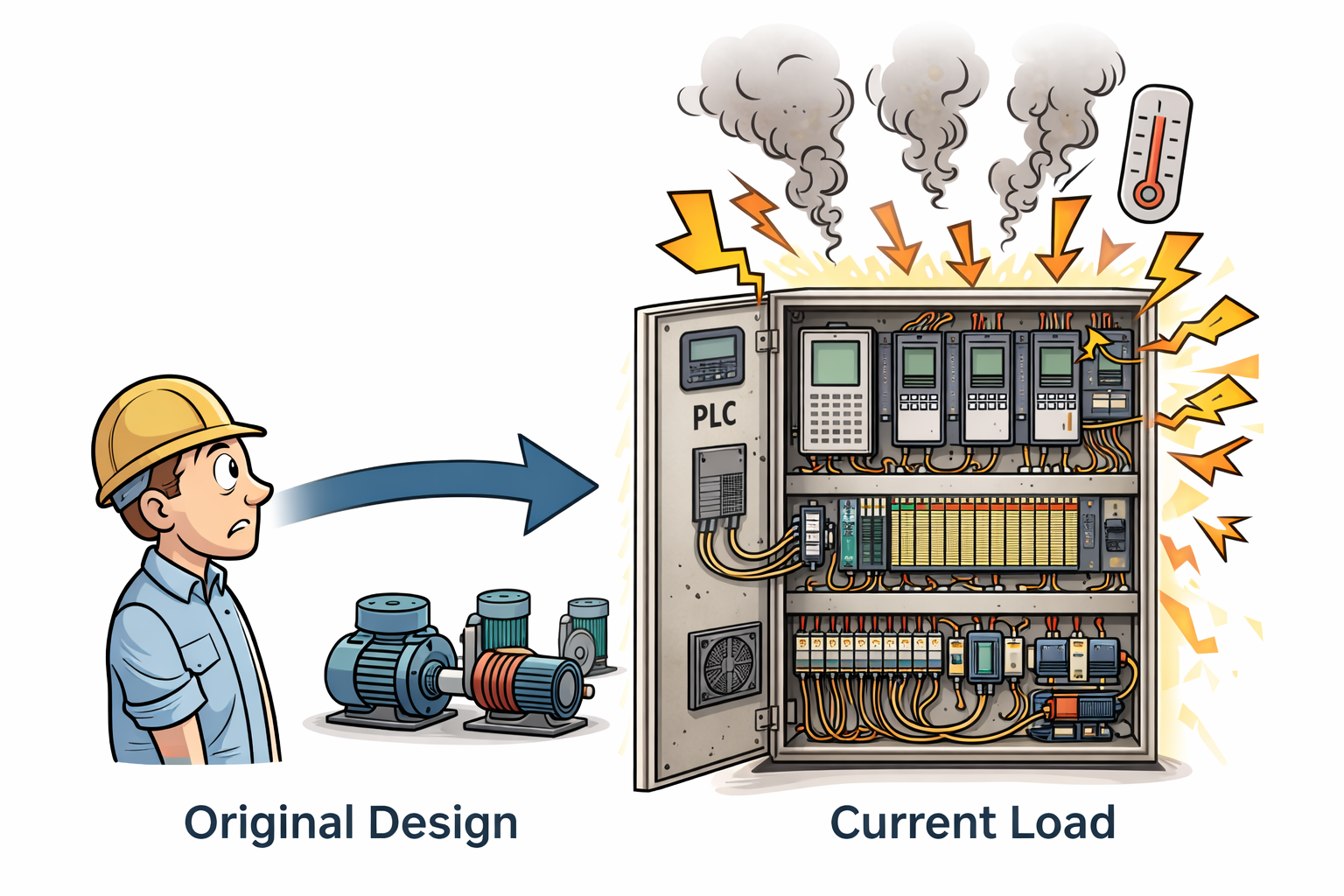

Growth Exposes Old Assumptions

Communities grow. Demand increases. Systems get pushed harder.

What does not grow along with them includes motor service factor, drive current capacity, cabinet cooling capacity, and physical space for expansion.

Many systems that ran reliably for years reach a breaking point because the original design margins are gone.

What BEA Recommends Instead

We focus on identifying single points of failure, verifying real world motor and drive loading, standardizing on supported hardware, improving SCADA visibility, and phasing improvements to match budgets and operational realities.

If your control system has worked for 20 years, that is not a reason to leave it alone. It is a reason to review it before it reminds you why.

|

|

| 2025-12-17 16:46:04 |

Rockwell Automation Announces the M100 Electronic Motor Starter

Rockwell Automation has introduced the M100 Electronic Motor Starter, designed to

simplify panel wiring and reduce component and engineering complexity while

delivering advanced functional safety and refined motor starting capabilities.

The M100 leverages point-on-wave switching technology to improve control of

electrical loads, reduce inrush current, and minimize electrical stress and

electromagnetic interference—helping improve system reliability and equipment life.

Read the full Rockwell Automation press release →

|

|

| 2026-01-13 16:21:07 |

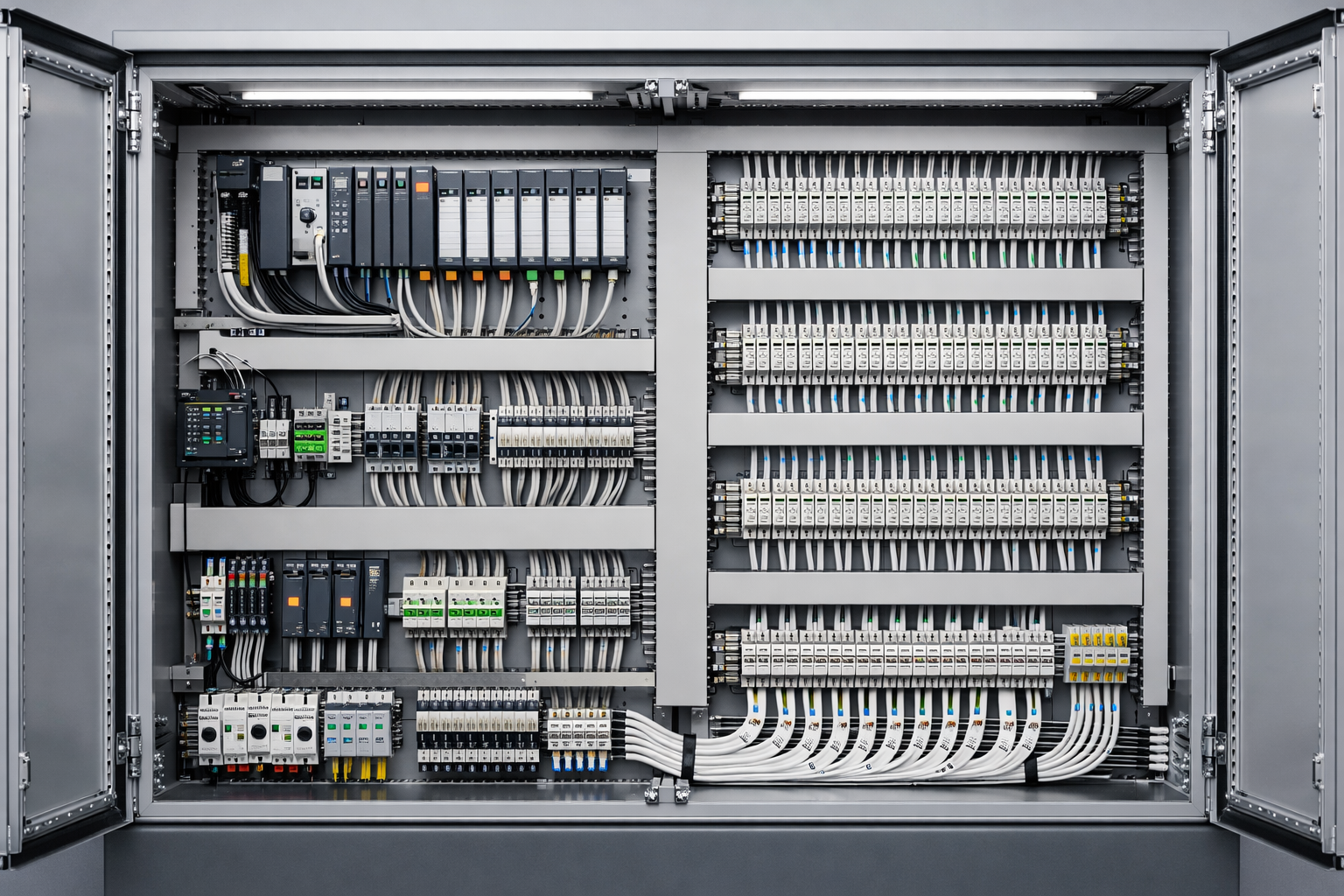

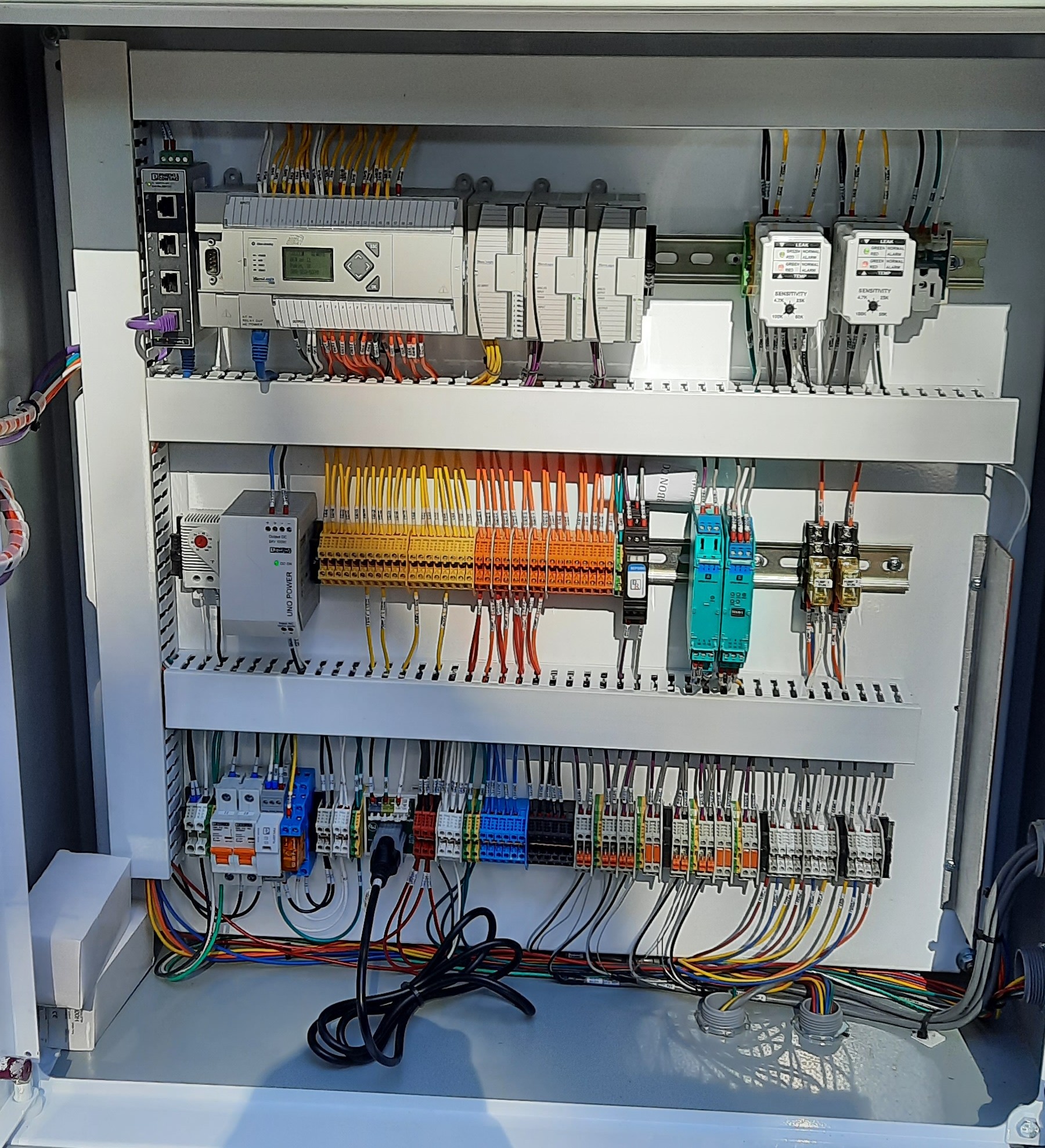

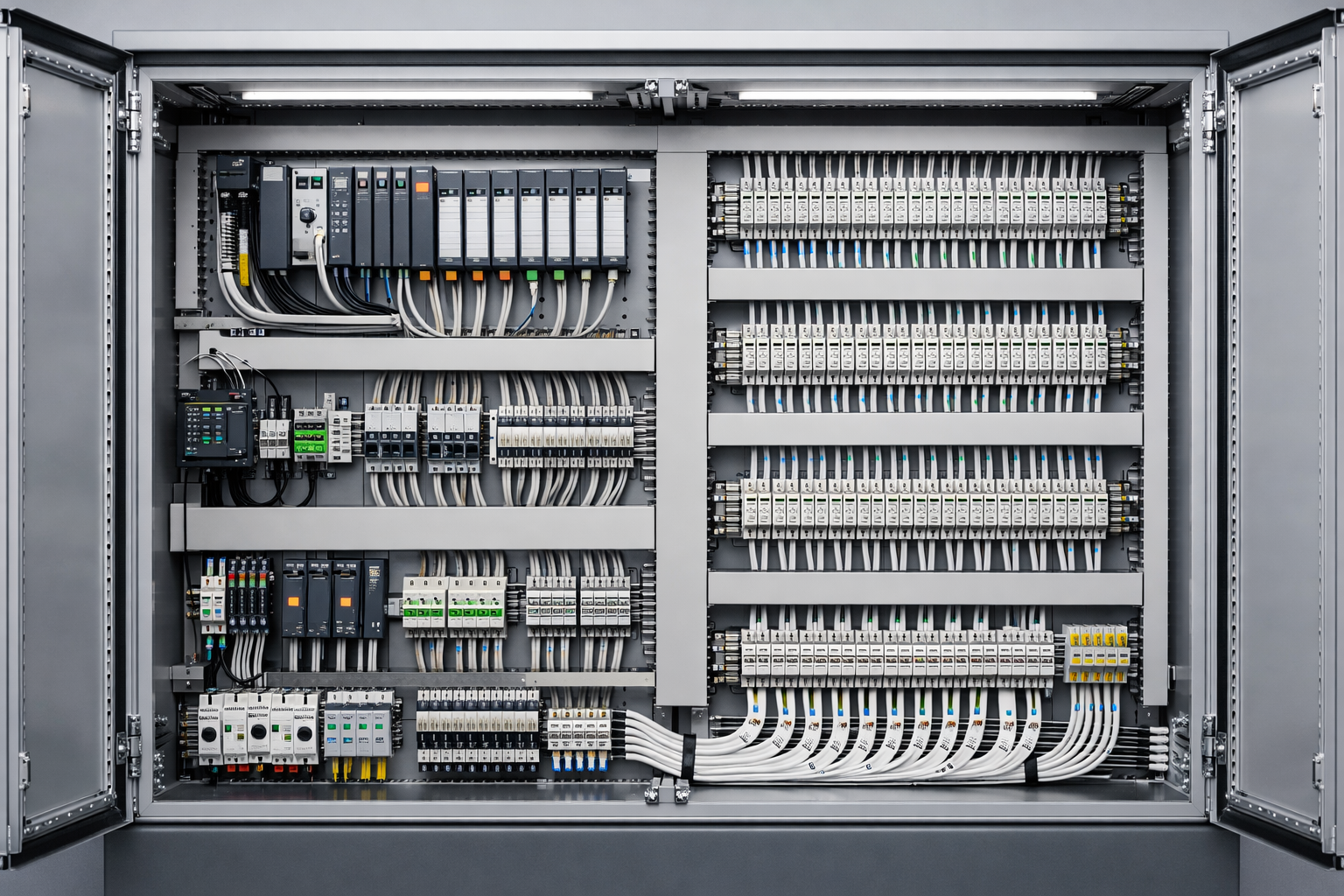

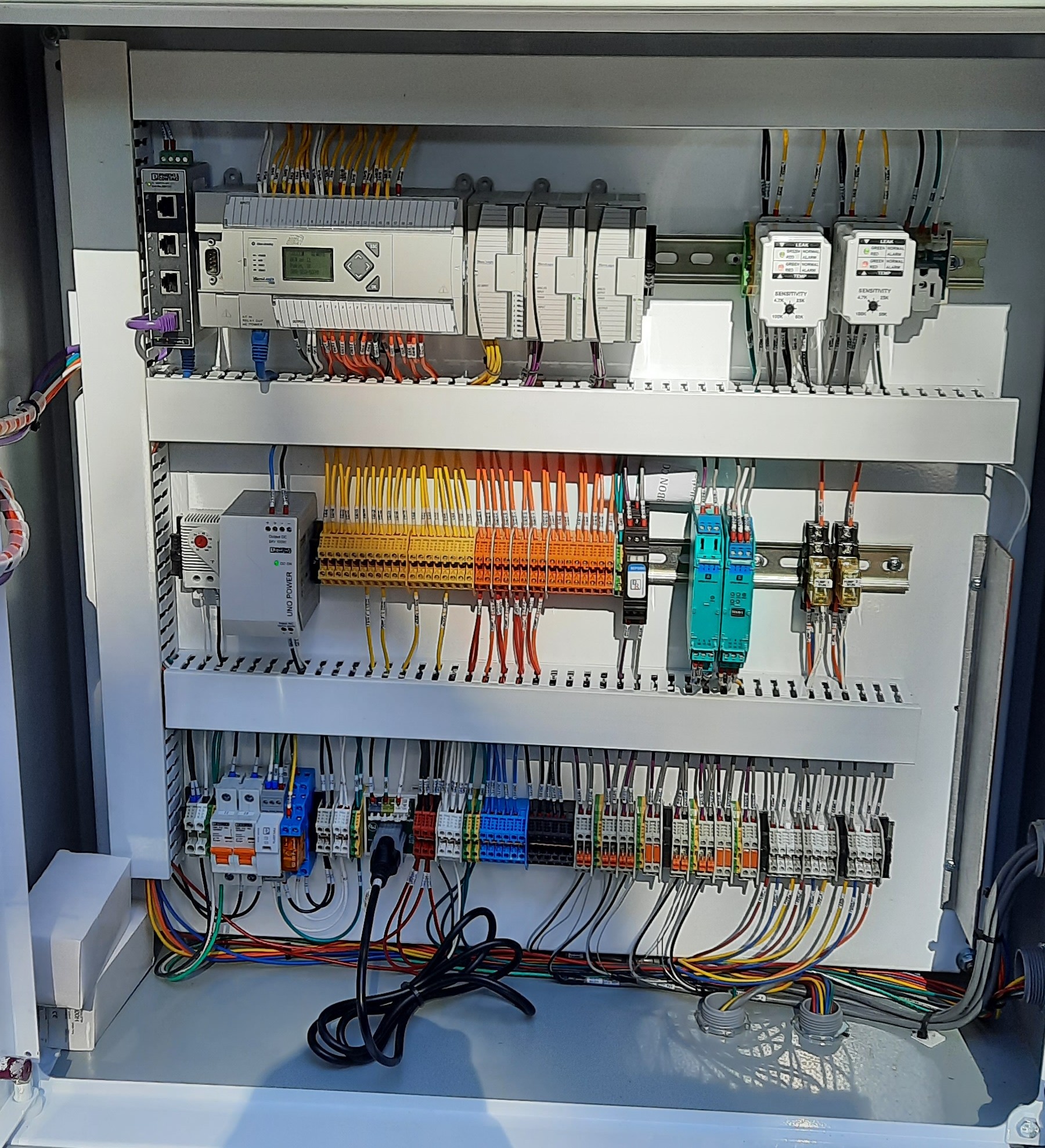

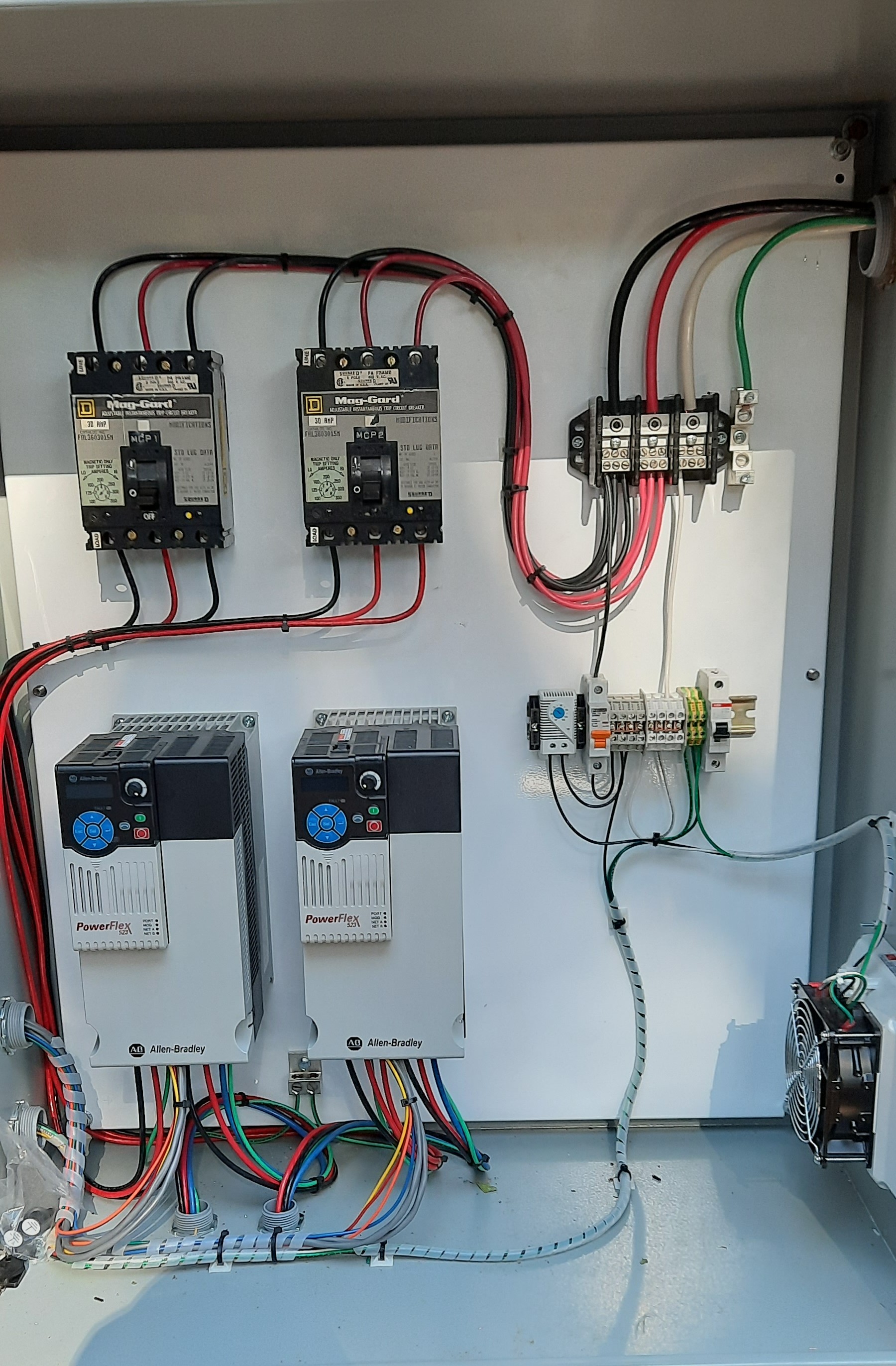

Why Good Wiring and Labeling Matter More Than You Think

Most people never see the inside of a control panel. If everything is working, there’s no reason to. But the moment something goes wrong, what’s inside that enclosure suddenly matters a lot.

Good wiring and clear labeling aren’t about making a panel look pretty. They’re about saving time, saving money, and keeping people safe, especially years down the road when the original installer is long gone.

Clean layout saves real time

When wiring is routed cleanly, bundled properly, and landed where it makes sense, troubleshooting becomes faster and less stressful. A technician can follow a circuit visually instead of guessing, tugging on wires, or pulling prints apart trying to decode a mess.

That time adds up. A clean panel can turn a two-hour service call into a twenty-minute fix. That’s less downtime for the customer and lower labor costs overall.

Labels prevent mistakes

Clear, consistent wire labels and device tags remove guesswork. When a wire is labeled correctly, there’s no confusion about what it feeds or where it goes. That matters when you’re working live, under pressure, or in a tight shutdown window.

Poor or missing labels increase the risk of disconnecting the wrong circuit, energizing the wrong device, or damaging equipment that wasn’t part of the problem. In the worst cases, it can put people in danger.

Future work becomes easier and cheaper

Panels rarely stay frozen in time. Systems get expanded, upgraded, or repurposed. When wiring is neat and labeling is accurate, adding a new device or modifying an existing circuit is straightforward.

When it’s not? Every change becomes slower, riskier, and more expensive. What should be a simple addition turns into hours of tracing wires and verifying everything twice just to be safe.

It reflects how the job was done

A clean, well-labeled panel usually tells you something important: the person who built it cared about the next person who would work on it. That mindset carries through the entire project — from design decisions to component selection to documentation.

Messy wiring often points to rushed work, shortcuts, or lack of planning. You may not notice it on day one, but it shows up later when something fails.

It’s about safety, not looks

At the end of the day, good wiring practices reduce risk. Clear routing lowers the chance of damaged insulation. Proper labeling reduces human error. Logical layout helps technicians work confidently instead of cautiously guessing.

Those details matter most when conditions aren’t perfectm, during emergency calls, night work, or unexpected failures.

Good wiring and labeling aren’t extras. They’re part of doing the job right, not just for today, but for everyone who has to touch that panel years from now.

|

|

| 2025-12-12 15:55:48 |

What Municipalities Should Know About Upgrading Old Pump Controls

Many municipal water and wastewater systems are still running on control panels installed decades ago. In many cases, those systems still work. The problem is not that they stopped working. The problem is what happens when they finally do.

Upgrading old pump controls does not have to mean a full system replacement or a budget breaking project. With the right approach, municipalities can modernize controls, improve reliability, and extend system life without unnecessary cost.

This guide outlines what small town water departments should understand before upgrading aging pump control systems.

Old Controls Fail Quietly Until They Do Not

Older pump controls often give little warning before failure.

Relays wear mechanically. Contactors pit and stick. Legacy PLCs lose battery backed memory.

Obsolete HMIs fail with no replacement available.

When failure happens, it often results in emergency service calls, downtime, or temporary bypass wiring that introduces new risks.

Proactive upgrades allow municipalities to plan costs instead of reacting to failures.

You Do Not Need to Replace Everything at Once

One of the biggest misconceptions is that modernization requires replacing the entire control system in one project.

In reality, upgrades can often be phased:

- Replace obsolete PLCs while keeping existing starters or VFDs

- Add modern monitoring and alarming without changing pump hardware

- Upgrade communications and remote access first

- Improve power protection and surge suppression incrementally

A staged approach spreads costs over time and minimizes operational disruption.

Modern Controls Improve Visibility and Diagnostics

Older control panels were designed to run pumps, not explain problems.

Modern control systems provide:

- Clear alarm messages instead of generic fault lights

- Runtime and cycle tracking

- Trending of pressure, flow, and level

- Easier troubleshooting for operators and technicians

Better visibility means faster response, fewer unnecessary callouts, and more confidence in system operation.

Standardization Matters More Than Features

Small municipalities often inherit a mix of equipment installed by different contractors over many years.

This creates challenges with training, spare parts, and support.

When upgrading pump controls, standardization should be a priority:

- Use a common PLC platform across sites

- Use consistent programming structure and naming

- Standardize HMIs and alarms where possible

Standardization reduces long term maintenance cost more than adding extra features.

Remote Monitoring Does Not Have to Be Complicated

Many older pump systems require on site checks to confirm status.

Modern upgrades can add remote visibility without full SCADA replacement:

- Cellular or radio based alarming

- Simple web based dashboards

- Secure remote access for troubleshooting

Even basic remote alarming can significantly reduce response time and operator workload.

Budget Planning Is Easier With Clear Scope

Upgrades often fail at the budgeting stage due to unclear scope.

A well defined scope of work helps municipalities:

- Understand exactly what is being upgraded

- Separate necessary upgrades from optional improvements

- Compare proposals fairly

- Avoid surprise costs during installation

Clear scope leads to predictable outcomes.

BEA’s Approach to Municipal Control Upgrades

At Britton Electronics and Automation, we focus on practical upgrades that improve reliability without overengineering.

Our goal is to modernize systems in a way that:

- Fits municipal budgets

- Maintains operator familiarity

- Improves long term serviceability

- Avoids vendor lock in

Every municipality is different. The right upgrade path depends on system condition, staffing, and long term plans.

Modernizing old pump controls is not about chasing the newest technology. It is about reducing risk, improving reliability, and giving operators better tools to do their job.

With the right planning, municipalities can upgrade aging control systems responsibly and cost effectively.

|

|

| 2025-12-12 12:07:36 |

Why Industrial Automation Projects Need Clear Scope of Work Documents

In industrial automation, most project problems do not start in the field. They start on paper.

Automation projects involve hardware, software, communications, power, and process integration. When the scope of work is unclear or incomplete, the result is almost always delays, unexpected costs, strained relationships, and change orders that could have been avoided.

A well written scope of work is not just a formality. It is one of the most important risk management tools in any automation project.

Scope Defines What Is Included and What Is Not

One of the most common causes of conflict on automation projects is assumption.

If a scope does not clearly state what is included, everyone fills in the gaps differently. The owner assumes something is included. The contractor assumes it is not. Both sides believe they are correct.

A strong scope of work clearly defines what equipment is being supplied, what services are being performed, what is explicitly excluded, and what the customer is responsible for.

Clear definition up front prevents disagreement later.

Clear Scope Prevents Scope Creep

Scope creep is rarely intentional. It usually happens one small request at a time.

Can you add one more alarm

Can you tie in this extra signal

Can you tweak the logic just a little

Without a clear scope, it becomes difficult to separate what is part of the original project from what is additional work.

A detailed scope of work creates a reference point. It allows changes to be evaluated objectively before they impact cost or schedule.

Good Scope Documents Protect Project Schedules

Automation projects are highly interdependent. Electrical work, mechanical installation, programming, testing, and startup all rely on each other.

When the scope is vague, tasks are added late in the project. Late changes disrupt testing plans, delay commissioning, and often push projects past critical deadlines.

A clear scope supports better scheduling, more accurate labor planning, and fewer last minute changes during startup.

The result is a smoother commissioning process and faster system turnover.

Scope Sets Expectations for System Behavior

In automation, details matter.

How the system behaves during faults

What alarms are required

What data is logged

What remote access is provided

If these expectations are not written into the scope, they are open to interpretation. That is when disappointment happens even if the system technically works.

A well written scope describes system behavior in plain language so success is clearly defined before the project begins.

Clear Scope Reduces Change Orders and Disputes

Change orders are sometimes necessary. They are not inherently bad.

Problems arise when change orders result from unclear scope rather than actual changes to the project.

When scope is well defined, legitimate changes are easier to identify, pricing is clearer, and trust between all parties is maintained.

Projects stay professional instead of adversarial.

Why BEA Emphasizes Scope of Work Clarity

At Britton Electronics and Automation, we treat scope of work documents as engineering tools, not paperwork.

Our goal is to eliminate surprises for our customers. Clear scopes lead to better projects, cleaner startups, and systems that perform as expected long after turnover.

Time spent defining scope at the beginning of a project saves far more time and cost at the end.

|

|

| 2025-12-12 12:00:09 |

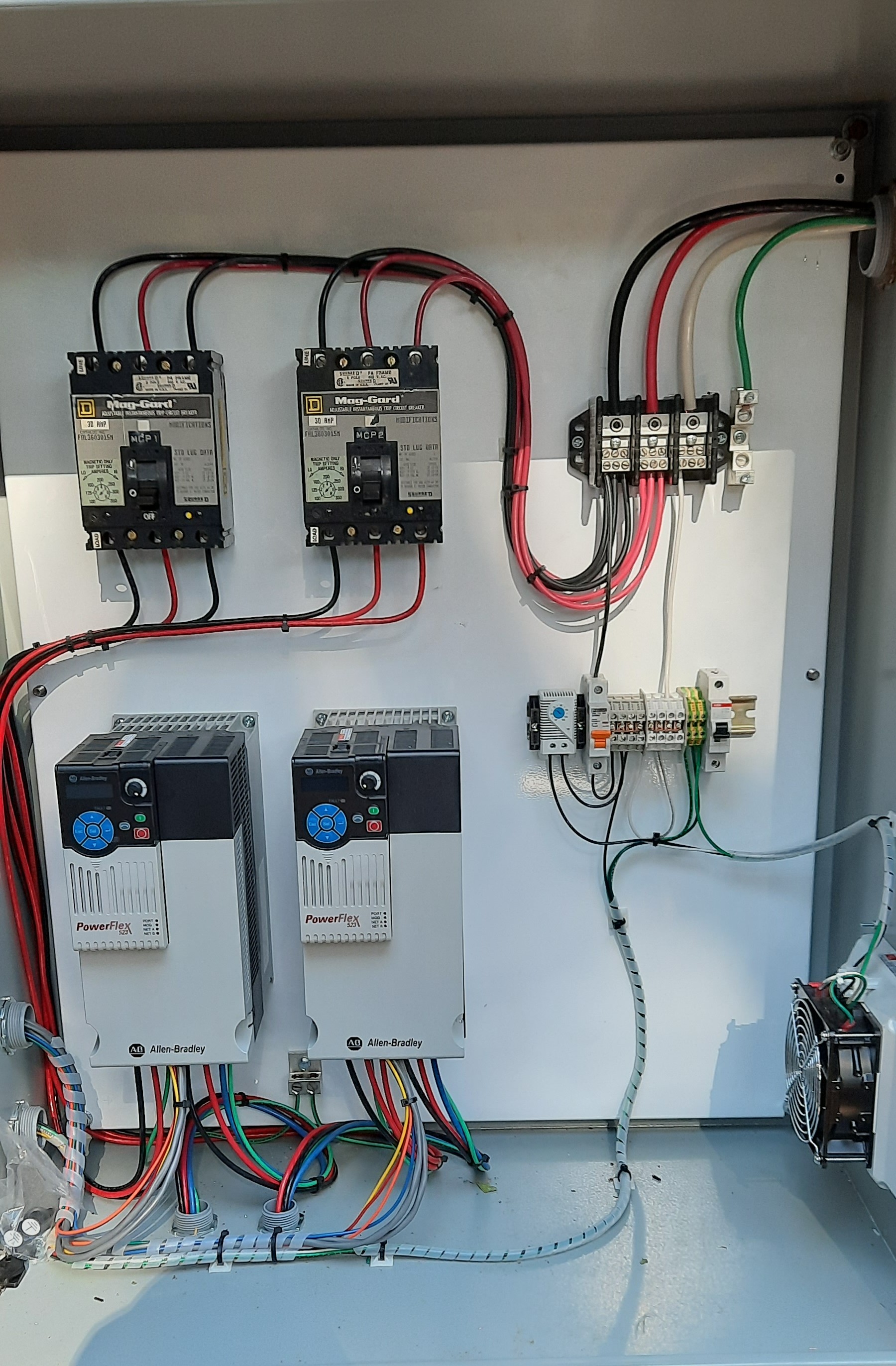

The Top 5 Reasons We Standardize on Allen-Bradley for Municipal Projects

When it comes to municipal infrastructure such as water, wastewater, lift stations, and public utilities, reliability, supportability, and long-term ownership matter more than novelty.

At Britton Electronics & Automation (BEA), we deliberately standardize on Allen-Bradley (Rockwell Automation) platforms for most municipal projects. This decision is not about brand loyalty. It is about reducing risk for our customers and ensuring systems remain serviceable for decades.

Below are the five core reasons we recommend Allen-Bradley as the standard for municipal automation

1. Local Support When It Actually Matters

Municipal systems do not fail on a convenient schedule.

Allen-Bradley has one of the strongest local distributor and support networks in North America. This provides faster access to replacement hardware, local technical support instead of distant call centers, and on-site assistance when time is critical.

When a lift station is alarming at two in the morning or a well is offline, local support is essential.

2. Long Product Lifecycles and Predictable Roadmaps

Municipal automation systems are not disposable.

Allen-Bradley products are known for long production runs, clear end-of-life notices, and documented migration paths. This allows municipalities to plan upgrades years in advance instead of being forced into emergency replacements due to discontinued hardware.

Predictability lowers lifecycle cost even if initial hardware pricing is higher.

3. Industry-Standard Training and Workforce Familiarity

Allen-Bradley is the most widely used PLC platform in North American municipal and industrial environments.

This makes onboarding new technicians easier, increases the number of available integrators and contractors, and ensures maintenance staff work with familiar tools.

Standardization reduces training costs and prevents systems from becoming black boxes that only one person understands.

4. Proven Reliability in Harsh Environments

Municipal control systems operate in real-world conditions that include heat, cold, moisture, vibration, electrical noise, and power disturbances. Many are installed in remote locations with limited access.

Allen-Bradley hardware has a long track record of surviving these environments with minimal downtime. When failures do occur, diagnostics are clear and recovery is straightforward.

Reliability is field-proven, not theoretical.

5. Clear Ownership of Code and System Design

At BEA, we believe the customer owns the system.

With Allen-Bradley platforms, code is accessible and well-documented, there is no proprietary lock-in to a single vendor, and multiple qualified integrators can support the system.

We write clean, structured logic so municipalities are never dependent on a single contractor to keep critical infrastructure running.

Standardization Is About Risk Reduction

Standardizing on Allen-Bradley is not about saying other platforms cannot work. It is about minimizing operational risk.

For municipalities, the real costs extend beyond hardware pricing. Downtime, emergency service calls, training gaps, and unsupported systems all add up quickly.

By standardizing on a proven platform, municipalities gain faster troubleshooting, lower long-term costs, and greater confidence in system longevity.

Our Commitment

BEA will always recommend what we believe is best for the customer, not what is cheapest or most convenient in the moment.

For most municipal applications, Allen-Bradley provides the strongest combination of support, reliability, and long-term value. That is why we standardize on it.

|

|

| 2025-06-26 15:39:24 |

The Real Difference Between Industrial and Consumer-Grade Networking Hardware

In the age of plug-and-play networking, it’s easy to assume that a $50 office switch or Wi-Fi router can do the job just fine—until it doesn't. In industrial environments, these assumptions lead to frustrating downtime, unexplained communication failures, and costly troubleshooting.

Let’s break down why consumer-grade networking gear fails in industrial settings, and what makes industrial-grade networking hardware the better choice.

1. Designed for Harsh Environments

Consumer Gear:

Made for temperature-controlled, clean office spaces. Exposure to dust, vibration, or heat often leads to early failure or inconsistent behavior.

Industrial Gear:

Built to operate in harsh conditions—dust, moisture, electrical noise, extreme temperatures, and vibration are all accounted for. Many industrial switches come with metal housings, conformal coating, and a wide operating temperature range (-40°C to 75°C is common).

2. Power Supply and Mounting Differences

Consumer Gear:

Typically powered via a wall-wart power supply with no redundant power input. Mounting options are limited, often requiring shelves or makeshift brackets.

Industrial Gear:

Supports 12–48V DC power input, often with redundant power connections. DIN-rail or panel mounting makes installation clean, compact, and secure within control panels.

3. Network Stability and Uptime

Consumer Gear:

Prone to intermittent performance and slow recovery after power cycles. Often lacks watchdog timers or robust memory buffering.

Industrial Gear:

Engineered for uptime. Watchdog timers auto-reboot devices when anomalies are detected. Industrial switches often support ring redundancy protocols (like MRP or RSTP) to ensure fast failover if a connection is lost.

4. Noise and EMI Resistance

Consumer Gear:

Minimal shielding, susceptible to electromagnetic interference (EMI) common in industrial plants—especially around motors, VFDs, and switching relays.

Industrial Gear:

EMI-hardened with shielding, isolation, and certifications for use in environments with high electrical noise. Often certified to standards like EN61000 for immunity.

5. Longevity and Support Lifecycle

Consumer Gear:

Short support lifecycle, minimal firmware updates, and limited logging or diagnostics. Meant to be replaced often.

Industrial Gear:

Designed for long-term availability and support—some manufacturers guarantee product availability for 10+ years. Advanced logging, SNMP, syslog, and managed switch features allow for easier diagnostics and integration.

6. Security and Management Features

Consumer Gear:

Basic or no VLAN support, minimal remote management, and few security features. Web GUIs are often stripped-down or proprietary.

Industrial Gear:

Comes with robust managed features: VLANs, QoS, SNMP, RADIUS, MAC filtering, port security, and remote monitoring. Many industrial devices support configuration backups, CLI, and secure protocols like SSH and HTTPS.

Bottom Line: Use the Right Tool for the Job

Using office networking gear in a plant is like trying to run a marathon in flip-flops—possible, but you'll regret it quickly. The upfront cost savings are often erased by a single day of downtime or a few hours of frustrating diagnostics.

Industrial-grade networking hardware is purpose-built for reliability, durability, and uptime—and in a production environment, those aren’t luxury features—they're requirements.

|

|

| 2025-06-23 16:56:18 |

The Hidden Costs of Low-Bid Control Panels

Choosing the cheapest control panel bid may seem like a way to save money, but it often leads to higher long-term costs.

What UL508A Covers (and Doesn’t)

● UL508A listing alone is not enough — UL508A ensures basic electrical safety, but not functional design quality or performance.

● Poor wiring layout — UL508A mandates safe clearances, but not service-friendly wire routing or panel layout.

● Cheap components fail more often — UL508A requires properly rated parts, but not high reliability or long life.

● Bad design practices (UPS failover, alarm logic, etc.) — UL508A does not evaluate control logic or alarm handling — that’s up to engineering.

● Improper use of basic relays for safety — UL508A allows basic relays if they meet rating, but modern safety design calls for certified safety relays and risk assessment.

● Improper PLC mounting voiding warranty — UL508A checks temperature spacing, but not manufacturer-specific mounting requirements.

● Lack of future proofing — UL508A has no provisions for expansion space or system scalability.

Common Problems We See in Low-Bid Panels

● UL508A listing alone is not enough: Some low-cost builders will deliver a UL508A-certified panel that is still poorly designed. Simply meeting the certification does not guarantee good engineering.

● Poor wiring layout: Inexpensive panels may not provide proper space or entry points for field wiring, causing field installation delays and creating maintenance headaches later.

● Low-grade components: Using cheap relays, terminal blocks, or power supplies increases the likelihood of frequent failures.

● Bad inherent design practices: Examples include wiring "power fail" detection circuits from the same source as the PLC power — when the power goes out, the PLC also shuts off, leaving no alarm or record.

● UPS auto-bypass without notification: Panels that auto-switch from UPS to non-UPS power but do not notify the operator leave critical equipment unprotected.

● Excessive or improper relay use: Failing to use proper interposing relays or not isolating PLC outputs can overload the PLC and reduce its lifespan.

● Improper PLC mounting: We have seen competitors mount PLCs in ways that violate manufacturer requirements, which can void warranties. Examples include vertical mounting when only horizontal is allowed, or mounting in high-heat locations inside the panel.

● Unsafe safety design: Some low-bid panels skip proper safety relays or controllers and instead use basic relays for emergency stops and safety interlocks. This practice can compromise the safety of operators and result in OSHA violations or increased liability.

● Lack of future-proofing: Low-bid panels often leave no space or provisions for future expansion, forcing costly rebuilds when system changes are needed.

Our UL508A Panel Build Philosophy

At BEA, we don't just "check the box" to meet UL508A minimum standards:

● We provide well-engineered, fully documented designs.

● We follow best practices for layout, wiring, and labeling.

● We follow manufacturer mounting and clearance requirements.

● We use industrial-grade components with proven field reliability.

● We properly design safety circuits with certified safety relays and risk reduction techniques.

● We build every panel with an eye toward future scalability and easy serviceability.

Our goal is to give you not just a "legal" panel — but one that will perform for years to come, reduce service costs, and protect both your equipment and your staff.

In the long run, a high-quality panel from a reputable builder will reduce total cost of ownership, improve reliability, and make life easier for plant staff and integrators.

|

|

| 2025-06-23 16:41:14 |

Why Standardizing PLC Hardware Saves You Money — And Headaches

If you own or manage an industrial facility — or a municipal water/wastewater plant — you’ve probably noticed this problem before:

Over time, as equipment is added or replaced, you end up with a patchwork of different brands and models of PLC hardware. One panel might have Allen-Bradley. Another might use Automation Direct. Maybe an older machine is still running a Siemens or Mitsubishi controller.

At first glance, this seems harmless. After all, “they all do the same thing,” right?

Well — yes, they all control equipment — but mixing too many brands can quietly create extra costs and problems that show up later when you least expect them.

Here’s why:

● Training your people gets harder.

Each brand of PLC has its own software, programming language quirks, and troubleshooting steps. When your staff has to learn several systems, it takes more time — and costs more for training. New hires also face a steeper learning curve, which can slow them down.

● Spare parts inventory grows unnecessarily.

You end up stocking parts for each different PLC platform — different power supplies, CPUs, communication cards, I/O modules, programming cables, and so on. That ties up money and shelf space, and increases the risk of grabbing the wrong part when you’re in a hurry.

● Making systems work together takes extra engineering.

When you want two different PLC systems to communicate, you often need special gateway modules or extra programming effort. This adds upfront costs and future maintenance headaches.

● Getting tech support can be inconsistent.

If a critical PLC goes down, it’s a lot easier to get help — or find a replacement part — when you’re using a common brand supported by local distributors. But if that failed controller is an uncommon or old brand, you might face long delays getting it fixed — or even a complete redesign of that control panel.

What we recommend — and why:

At Britton Electronics & Automation, we almost always recommend standardizing on a single platform for PLC hardware. For most of our customers in Illinois and across the Midwest — especially in the municipal water/wastewater world — Allen-Bradley is the best fit.

Why?

● It’s well-supported locally.

Distributors in the region stock plenty of AB hardware, and there is strong technical support available.

● It’s reliable and proven.

We’ve seen Allen-Bradley systems perform very well in tough environments — pumping stations, treatment plants, factories — year after year.

● It protects your investment.

Even older models of AB PLCs have long-term support and parts availability. This isn’t always true with some of the cheaper brands.

● It simplifies training and reduces errors.

Your team only needs to master one programming environment — which saves time, prevents mistakes, and makes your operation more efficient.

Bottom line:

Choosing to standardize your PLC hardware might not sound exciting, but it is one of the smartest ways to save money and avoid problems down the road.

When you have one consistent hardware family across your plant — your people get faster at troubleshooting, your inventory shrinks, your systems integrate better, and your risk of unplanned downtime goes down.

If you’d like help reviewing your current PLC landscape — or if you’re planning upgrades and want to avoid a mix of brands — give us a call. We can help you build a roadmap that makes future expansions easier, smoother, and more cost-effective.

|

|

| 2024-04-26 17:24:28 |

Safety Controls Made Simple Safety Controls Made Simple

The GC Series consolidates any and all safety controls into one simple device. Any safety device can connect to this series and the new GC-Link can be used to eliminate wiring entirely. The GC can be expanded to 212 inputs and has an optional built-in relay output.

|

|

| 2024-04-26 17:01:15 |

TRIO power supplies with integrated circuit breaker

Plug-and-play solution for the control cabinet

Middletown, Pa. – The TRIO Power 24 V power supply from Phoenix Contact features a space-saving design, easy handling, and smart diagnostic functions. Output currents range from 5 to 40 A. The line includes options with an integrated multichannel circuit breaker.

The power supplies’ narrow overall width saves space, making it possible to mount them directly, side by side. The low overall depth enables installation in 210 mm small housings. Push-in connection technology, marking fields, stripping identification, and tamper-proof setting make the TRIO easy to install and handle. The devices have an intuitive commissioning concept for quick deployment.

In addition, the power supplies have several diagnostic options. The multicolor LEDs and a collective relay contact signal important states, such as DC OK, overload, and short circuit. An optional IO-Link interface is available for diagnostics and parameterization. With up to 960 W output power in 1 AC and 3 AC versions, the power supply is suitable for drive technology. The dynamic boost (150 percent for five seconds) also enables difficult loads to be started. With the powerful output characteristic curve, even capacitive loads can be charged without any problems. The optional built-in electronic circuit breaker offers high system availability.

The power supplies with integrated multichannel circuit breaker are rated for NEC Class II and Class I, Division 2 applications.

|

|

| 2023-11-16 18:03:09 |

|

We're very pleased to announce that the GracePESDs® 5-Wire Safe-Test Point™ has taken the GOLD award in the Safety & Security category of Plant Engineering's 2021 Product of the Year Program! This is the third time we have been awarded recognition by Plant Engineering for outstanding products.

The GraceSense™ ControlGate took the BRONZE award last year in the IIoT category and the Vibration & Temperature Node took SILVER in 2019. To celebrate the Safe-Test Point being recognized as the best product submitted in the Safety & Security category, we are offering a free sample of the Safe-Test Point!

"The finalists of the 34th annual Plant Engineering Product of the Year awards varied across 15 categories. This program honors the best innovations of 2021, as voted by the audience of Plant Engineering. The 2021 Product of the Year Grand, Gold, Silver, and Bronze award winners are honored in the May/June 2022 issue of Plant Engineering magazine." -Plant Engineering

Arc flash and shock hazards most commonly occur during Lockout/Tagout (LOTO) procedures where direct contact and exposure to live voltage are possible. The Safe-Test Point limits this contact and exposure by allowing qualified personnel to safely perform LOTO procedures and test for absence of voltage with a panel door closed. The high-impedance protected test points allow a multimeter to measure AC/DC voltages either phase-to-phase, phase-to-ground, phase-to-neutral, or neutral-to-ground.

|

|

| 2023-11-16 18:22:38 |

|

AC/DC In-Line Power Converter

Integrate DC Devices Into a Work Area with AC Power

The new SPS30 AC/DC In-Line Power Converter is a compact, cost-effective device that makes it easy to connect sensors and indicators that use DC power to a production line using AC. The SPS30 accepts 100–240 V AC at its input and converts that voltage to 24 V DC at its output. Specifically, it converts a DC sensor’s output to a Normally Open 4-amp electromechanical SPST relay for switching AC or DC loads. In addition, the converter’s AC input line is available to remotely teach a sensor or activate an actuator. Separate SPS30 models feature either 4-pin M8 or 5-pin M12 connectors.

|

|

| 2023-11-16 18:06:42 |

FL SWITCH EP 7400 Series

Substation hardened managed switches Advanced network platform for electric power systems

The FL SWITCH EP 7400 series of advanced modular managed network switches provides an adaptable platform to meet the electric power industry’s increasing requirements for scalable network performance, uptime, and security. The modular 19" rack-mount switch is hardened for areas heavily affected by EMI, such as switchgear, transformer stations, and local substations. The switch works reliably under extreme environmental conditions (-40°C to +75°C / 85°C) and complies with the IEC 61850-3 Ed 2, and IEEE 1613 specifications. The expandable “all gigabit capable” architecture combines cost-effective answers for near-term needs with upgrade paths for port quantity/bandwidth and functions. A powerful Layer 2 and Layer 3 feature set with hardware-based IEEE 1588 V2 PTP synchronization based on the IEC 61850-9-3 Utility Power Profile provides extensive options to meet changing performance and security needs. The 28-port switch has 4 module slots. 3 slots accept 10/100/1000Mbps port modules (up to 8 ports) for device connections, and a 4th slot supports a 4-port SFP module with 1 or 10 Gigabit uplinks for device connections. SFP module options provide further single-point TX/fiber connection customization, while allowing for electrically isolated and secure communication lines between the control house and equipment throughout the station. Power is provided by redundant modular power supplies. The modules are designed for power source flexibility (AC/DC) and allow hot-swappable replacement for uninterrupted 24/7 operation.

|

|

| 2022-04-14 18:18:52 |

New generation web panels New generation web panels

The new WP 6000 web panel product family from Phoenix Contact is a flexible platform that carries out operation and monitoring tasks efficiently.

The web panels are scalable across display sizes and offer flexible mounting options. With the Linux operating system and the Qt/HTML5 web browser, the devices have their place in any automation system that uses web-based applications. With new capacitive glass touchscreen technology and a metal housing, high-grade craftsmanship and quality make these panels the sure choice. The high-performance operator panels can have up to four tabs open at a time. Web panels with display sizes of 12.1″ and larger are equipped with a proximity sensor that allows for the screen’s backlight to be auto-dimmed or switched off entirely. What’s more, applications that aren’t web-based can also be run with the integrated VNC server. Device setup is simple and straightforward with the built-in Cockpit.

Read more

|

|

| 2021-10-27 17:05:18 |

for Fiscal Year 2020 (Oct. 1, 2019, to Sept. 30, 2020)

The following is a list of the top 10 most frequently cited standards following inspections of worksites by federal OSHA. OSHA publishes this list to alert employers about these commonly cited standards so they can take steps to find and fix recognized hazards addressed in these and other standards before OSHA shows up. Far too many preventable injuries and illnesses occur in the workplace.

|

|

| 2023-11-16 18:09:16 |

|

By Nick Schiltz, Apr 21, 2021 1:30:00 PM

Last month, the official OSHA Top 10 Violations for 2020 were published after an understandable delay not unlike what we had all grown accustomed amid the pandemic. This year’s Top 10 saw the Standard (1910.147) for The Control of Hazardous Energy (Lockout/Tagout) drop down to the #6 spot with 2,065 total violations; 541 less than the previous year. Each year, safety conscious employers depend on the OSHA’s Top 10 Most Cited Violations data to better inform them on the riskiest scenarios in their safety programs. The total violations are typically released at the end of the fiscal year in September.

Read more

|

|

|

| 2023-11-16 18:11:54 |

|

Safety Should be Part of Cybersecurity

To better protect physical assets, workers and compliance, it’s vital to understand the link between safety and security risks and how to mitigate them.

|

|

By Steve Ludwig, commercial programs manager, Safety, Rockwell Automation

The dangers that cyber threats pose to intellectual property, customer records and productivity are well known, but safety implications of these threats are discussed less often. A cyberattack on your industrial control system (ICS) can damage physical assets, alter recipes, injure workers or cause severe environmental damage.

If you’re on a digital transformation journey — whether it’s a managed process or slow evolution — managing the inherent safety and security risks should be an integral part of the process.

A properly designed security approach will improve information collection, analysis and delivery. It also will minimize security-related interruptions and frustrations. And it will help protect your enterprise.

Know Your Risks

|

|

|

| 2023-11-16 18:13:18 |

FL WLAN 4321: The easy Ethernet cable extender

Extend the range of your Ethernet network in a matter of seconds with the FL WLAN 4321 easy wireless bridge kit.

The FL WLAN 4321 is a pre-configured, high-speed, point-to-point wireless Ethernet bridge that allows wireless connection to remote locations of up to two miles. Just mount the hardware, apply power with the included POE injectors, and align the units using the built-in alignment LEDs.

4 easy steps to extend your network

- Unpack the hardware

- Mount the hardware

- Plug in the hardware

- Leave the hardware

FL WLAN 4321 easy wireless bridge kit

|

|

| 2020-11-19 17:57:33 |

Experience the benefits of In-Series Diagnostics (ISD) on standard safety devices with two normally

closed set of contacts—such as mechanical safety switches and panel-mounted E-stops—with the

new ISD Connect. A compact T-connector that fits in-line with other ISD devices, the ISD Connect

links a non-ISD device to a daisy chain of up to 32 devices. ISD makes it easy to access diagnostic

data from devices in a safety system without special equipment or designated cabling. Use it to

troubleshoot machine safety systems, prevent system faults, and reduce equipment downtime.

|

|

| 2023-11-16 18:14:49 |

THERMOMARK PRIME

THERMOMARK PRIME Phoenix Contact’s mobile thermal transfer printer enables you to print labels in card and sheet format for a wide variety of devices and mark each in exactly the right spot.

THERMOMARK PRIME, our reliable mobile thermal transfer printer, enables you to mark terminal blocks, conductors, cables, devices, and systems precisely where you want to. Card and sheet formats are available. THERMOMARK PRIME includes a rechargeable, high-performance battery and fully integrated marking software. You’ll find that the printing system is perfect for stationary use, but is designed especially to give you print capabilities on-site.

|

|

| 2023-11-16 18:19:05 |

Security routers – protect industrial networks easily

The new  security routers of the FL MGUARD 1100 series allow you to easily and inexpensively protect industrial networks against IT attacks. The on-board functions enable the fast startup of devices, even if you only have minimal network and security knowledge. security routers of the FL MGUARD 1100 series allow you to easily and inexpensively protect industrial networks against IT attacks. The on-board functions enable the fast startup of devices, even if you only have minimal network and security knowledge.

Your advantages

- Easy Protect Mode: without requiring any configuration, wire bridges are used to block external network access attempts

- The new Firewall Assistant helps you create firewall rules

- Test Mode: a straightforward test of the firewall rules created without limiting system availability

- Inexpensive entry into network security

- High data throughput

|

|

| 2020-09-30 16:44:10 |

1000 and 1100 series Unmanaged Switches

The latest generation in our portfolio of Unmanaged Ethernet Switches. These switches are suitable for many automation applications and feature different transmission speeds and installation options.

Simply unpack, connect, and use

The 1000 and 1100 series switches are fully Plug and Play capable, and do not need to be configured. Users therefore find them easy to operate and install. Furthermore, status LEDs on the front and side of the switches provide basic information on the connection status at a glance. This means that an interrupted connection, e.g., due to a faulty cable, can be diagnosed quickly.

|

|

| 2020-09-23 20:48:40 |

Zachary Stank

Product Manager Control, Safety, I/Os

Programmable logic controllers (PLCs) are extremely common across a variety of industries, including manufacturing, oil/gas, and transportation. Essentially, they are just another type of computer. Though they differ from PCs in many ways, Machine Design provides a succinct definition that highlights their differences: “a programmable logic controller is a digital computer designed for automation and industrial controls. It was created to resist to a wide range of operating conditions, including temperature, pressure, electrical noises, and vibrations. The most important feature that truly led to its success is that it is a hard real-time system.”

A PLC collects inputs, analyzes them with its internal logic, and then creates outputs based on that analysis. It repeats this cycle ad infinitum, all the while withstanding harsh environments. This makes PLCs dependable tools, and so businesses around the world rely on them in production environments.

Everything, however, has a limit. PLCs are no different. In fact, as we move towards Industrie 4.0 with the Industrial Internet of Things (IIoT), these limitations are becoming even more pronounced.

These are the top five things that PLCs can’t do.

|

|

| 2023-11-16 18:19:38 |

|

The world stands still - but technology continues to evolve. At the PHOENIX CONTACT Dialog Days April 27th – 29th, we would like to show you which ideas turned into innovations, which trends drive us and what our latest solutions look like. #stayincontact

Are you in?

https://phoe.co/DialogDays |

|

| |

|

|

|

|

| 2020-09-23 18:39:31 |

|

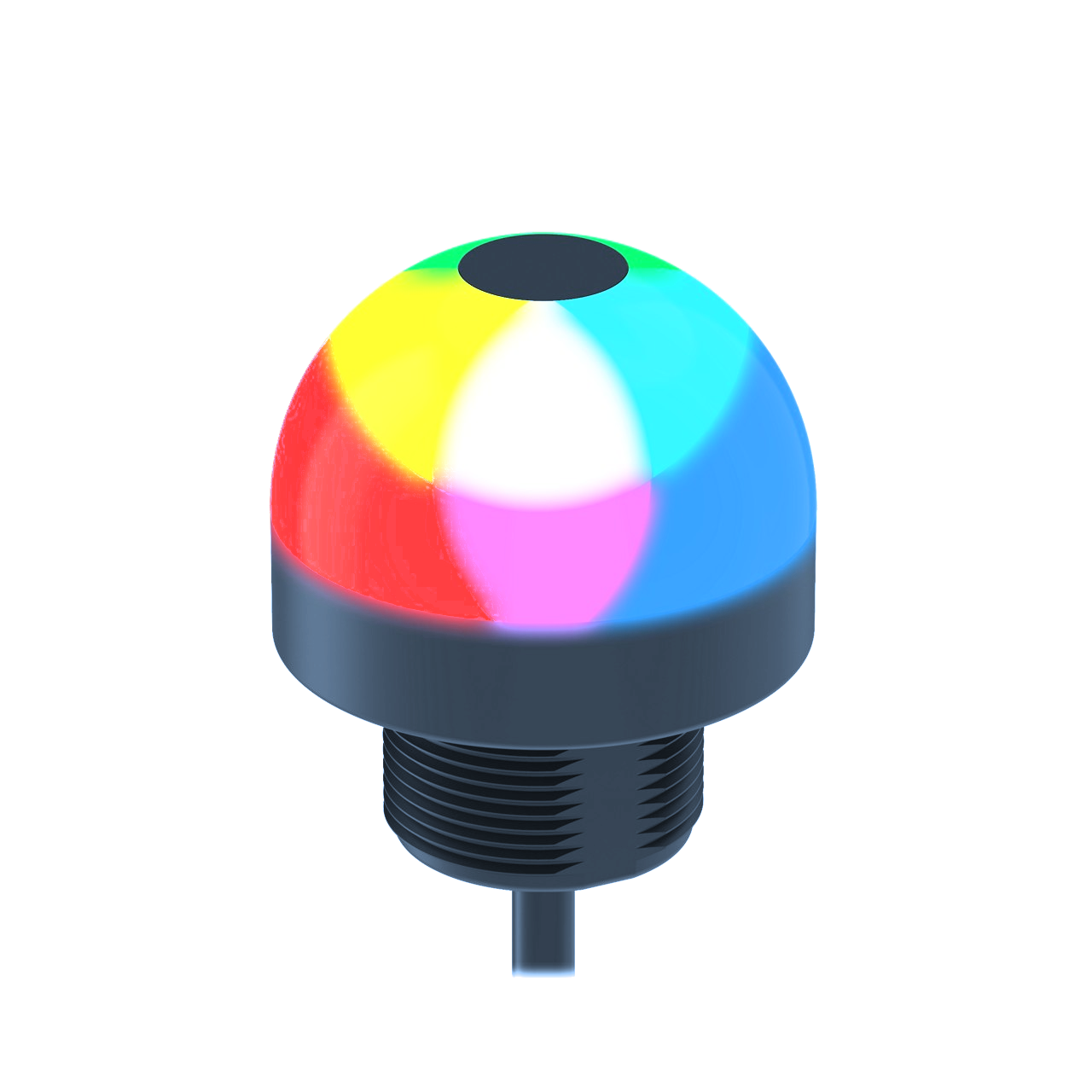

K50 Pro Series

Now with IO-Link and PICK-IQ

The K50 Pro Series of devices has expanded to include additional communication capabilities with IO-Link and PICK-IQ ® and optical and mechanical actuation. Each of these 50 mm multicolor RGB devices are now available with either IO-Link communication for advanced animation customization or PICK-IQ for faster response speeds over a Modbus network.

|

Learn More

|

|

| 2020-09-23 18:40:23 |

Quick-locking circular connectors

12/09/2019

M23 PRO circular series simplifies connection for signal and power transmission

Middletown, Pa. – The new M23 PRO circular connectors from Phoenix Contact offer uniform solutions for signal and power transmission. The patented ONECLICK quick-locking system makes it easy to connect devices quickly and safely.

With the ONECLICK system, the user can see, hear, and feel when the connection is made, ensuring that connectors are fully locked. The connectors, available in M23 up to 17 positions, are compatible with threaded and quick-locking metric connectors from other manufacturers.

|

|

| 2020-09-23 18:55:16 |

Enhancing Interoperability and Management of Vital Industrial Network Infrastructure

York, Pa. – November 20, 2019 – Red Lion Controls, global experts in communication, monitoring and control for industrial automation and networking, announced the release of their innovative new NT328G Layer 3 Ethernet switch today. Offering 28 high-speed ports (24-Gigabit, 4-10 Gigabit) and reliable wire-speed switching performance, the NT328G offers exceptional performance and reliability to meet the current and future needs of the Oil & Gas, Water & Wastewater, Energy, Transportation, and video and security sectors, as well as other bandwidth-intensive industrial applications.

Red Lion’s NT328G Layer 3 industrial Ethernet models feature a flexible mix of copper and fiber ports, allowing for a vast variety of connection options, with Layer 3 routing that provides the ability to route across VLANs or subnets—versatility that ensures scalability. The industrial-grade NT328G’s robust feature set includes network redundancy, advanced, integrated security, policy-based traffic control and easy-to-use configuration and management—reducing operating costs while providing continuous monitoring of network activity. Its sleek but rugged IP30 rackmount metal housing is constructed for long-life use in harsh industrial environments, including wide operating temperature conditions and hazardous locations—durability that ensures reduced downtime. Ideal for large-scale and/or any industrial network, the NT328G has the flexibility to meet both present and long-term speed and media requirements—delivering investment protection for years to come.

“Industrial customers are demanding reliable wire-speed Layer 3 switching performance that is scalable to 10Gigabit speed to meet current and future bandwidth-requirements. Customers now have access to a future-proof and durable switch solution that addresses industrial requirements from the network edge to the core.” said Diane Davis, director of product management at Red Lion Controls.

For more information about Red Lion’s new NT328G Layer 3 Ethernet Switch, visit www.redlion.net/NT328G.

|

|

| 2020-09-23 18:40:13 |

Vibration & Temperature Node

The Vibration & Temperature Node is a rugged wireless sensor with advanced edge processing and proprietary Zigbee compatible communication monitors vibration and temperature to insightfully predict health on any rotating equipment. Multiple mounting options ensure quick deployment across applications in any industry. Easy to replace batteries deliver 3-5 years of life (dependent on use).

|

|

| 2020-09-23 18:40:29 |

|

November 20, 2019

Industrial leader announces partnerships and collaborations with best-in-trade digital solutions to bring The Connected Enterprise to life

CHICAGO — Today, Rockwell Automation and members of its global PartnerNetwork program opened the 27th annual Automation Fair held in Chicago. The event sees record-breaking attendance of over 19,000 makers, builders and innovators from across the globe to attend industry forums, networking events and learn about the newest innovations in automation.

Blake Moret, chairman and CEO of Rockwell Automation, announced from the stage the formation of its Digital Partner Program. The new program includes significant collaborations with Accenture, a strategic partnership with ANSYS and accelerated work with Microsoft. Further progress and new developments in the partnership between Rockwell Automation and PTC also made news throughout the week.

|

|

| 2020-09-23 18:39:40 |

Wednesday, October 23, 2019

Crowne Plaza Hotel, 3000 S Dirksen Pkwy, Springfield, IL 62703

|

|

| 2020-09-23 18:40:18 |

|

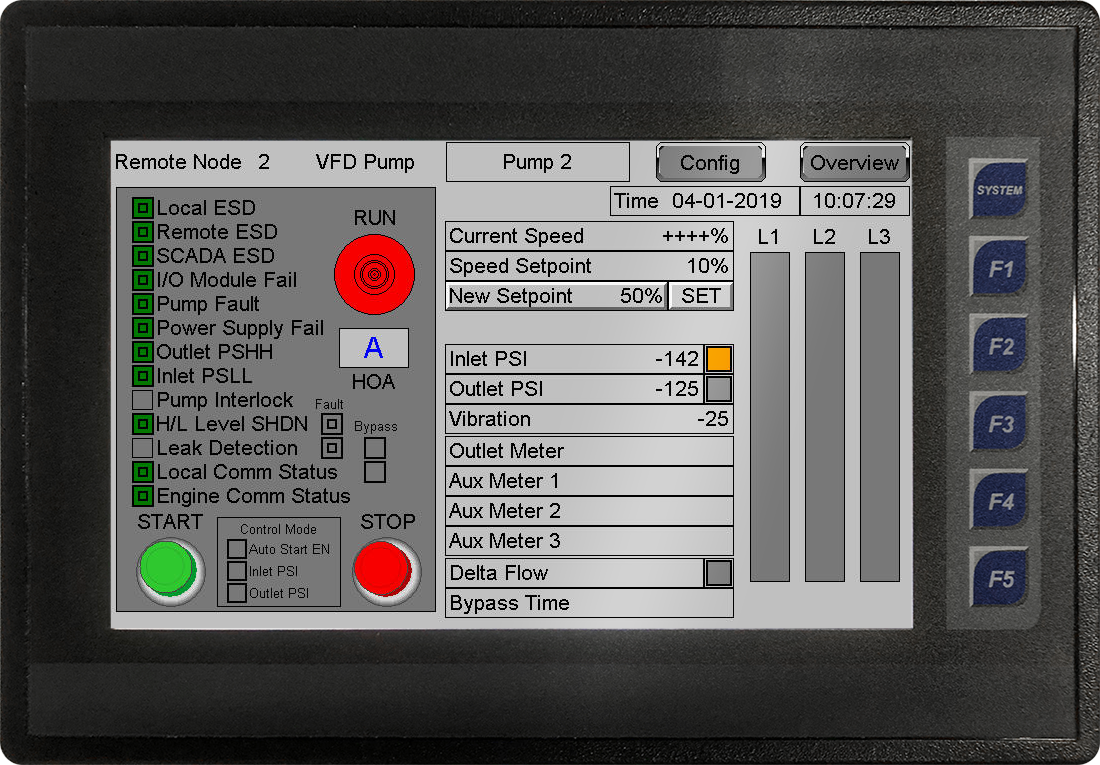

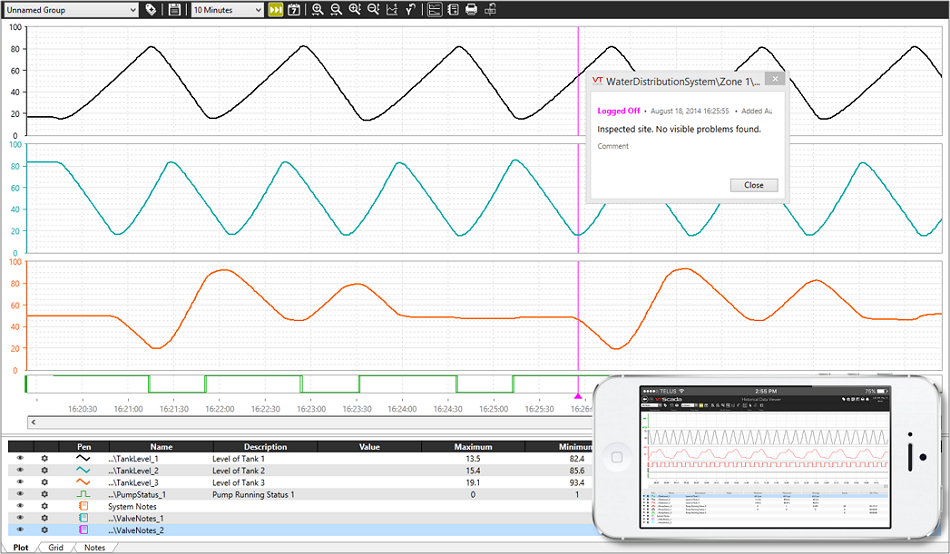

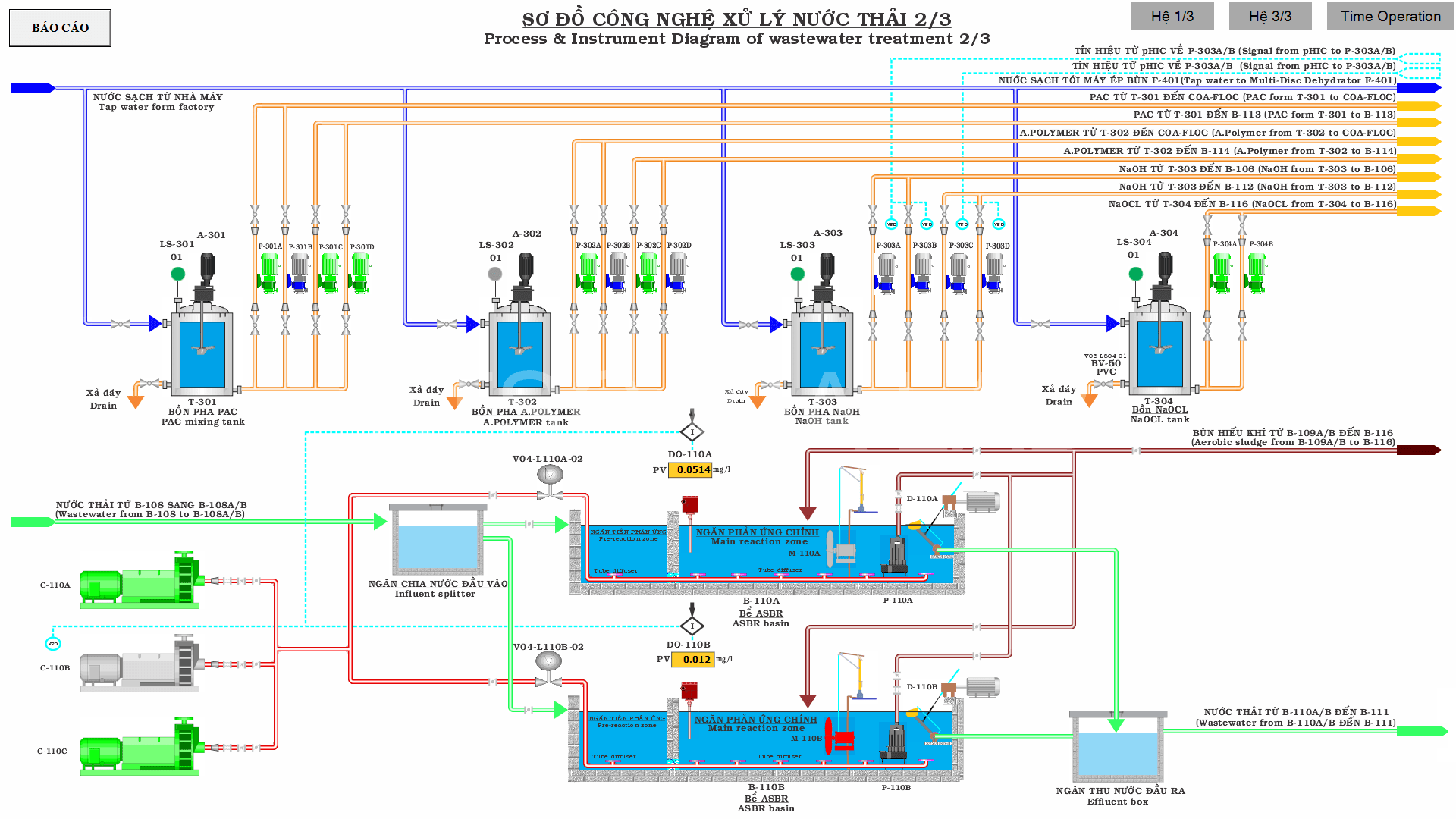

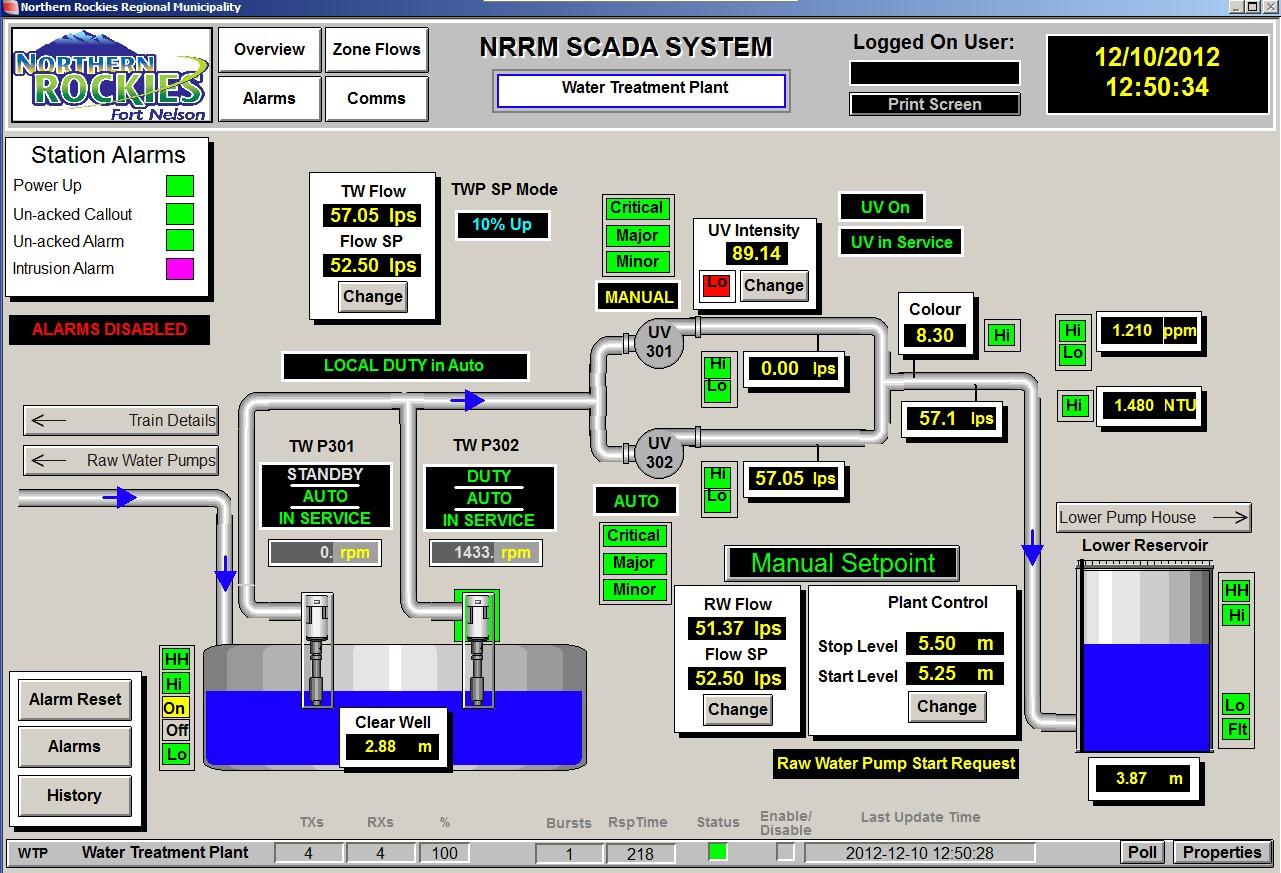

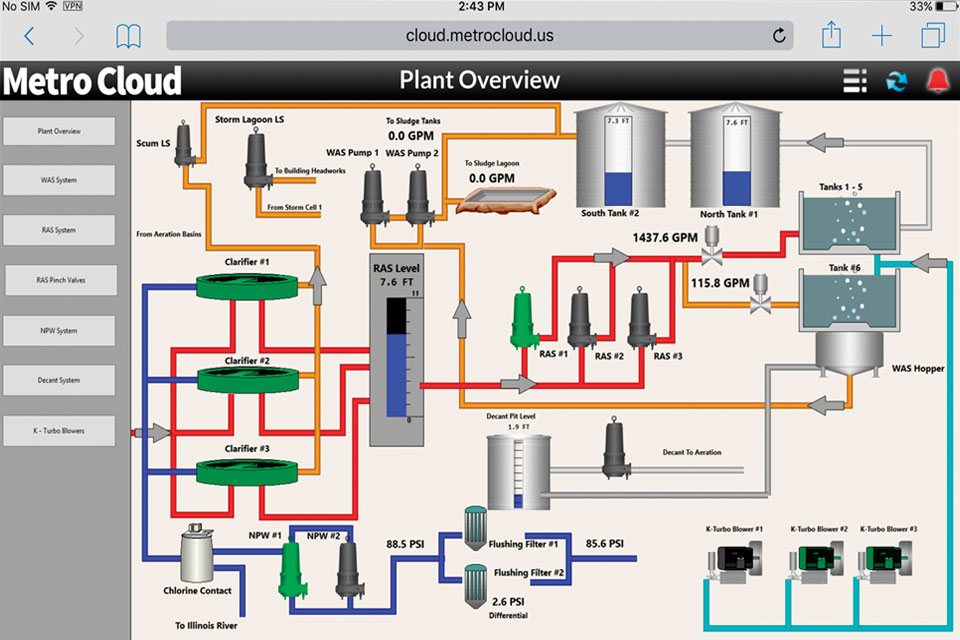

Water and wastewater systems don’t run themselves. A lot of sophisticated monitoring and automated control goes into ensuring a community’s water needs are met day in and day out. These include things like monitoring and controlling: Pump status (on/off/hours run) and flow rates, Water levels in wells and tanks, Sluice gate positions, Reservoir levels, Intrusion alarms and security measures One of the many [...]

|

|

| 2019-04-16 15:40:22 |

Great turn out for the Lunch and Learn with BEA and Endress+Hauser

Special event to learn about the latest technology in water and waste water analytical and measurement. How you can use these technologies to your advantage on the job every day.

WHAT WAS COVERED:

- Flow meter technology in the Connected Plant.

- How Digital Memosens Technology for Analytical Sensors (including Advanced Aeration control and Nutrient Analyzers and Turbidity can help you.

- Radar Level technology for Environmental Industry – FMR20 technology and Heartbeat for level detection.

Join Us on our next event..

|

|

|

.jpg)